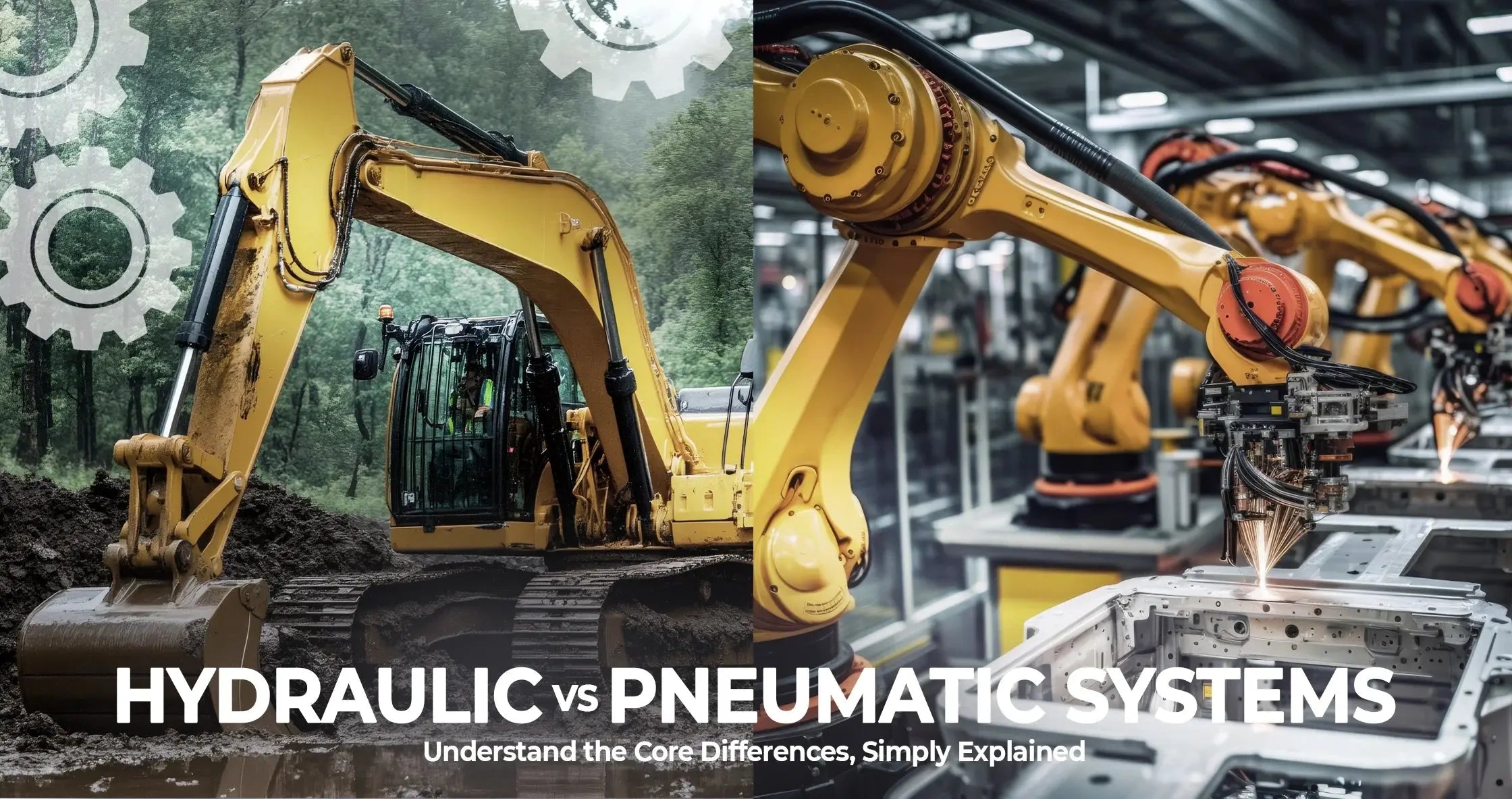

When it comes to powering industrial equipment, two major technologies stand out: hydraulic and pneumatic systems. Both are widely used across industries like manufacturing, construction, and automation, but they operate differently and serve distinct purposes. Understanding the differences between hydraulic vs pneumatic systems is essential for selecting the right system for your application. This article breaks down the core distinctions in simple terms, covering how each system works, their advantages and limitations, and where they're best suited for use.

Hydraulic and Pneumatic Systems: How do they Work?

Basic Principles of Operation

Hydraulic systems rely on pressurized liquids—typically oil—to transmit force and motion. Because liquids are nearly incompressible, these systems can generate high force with precision. In contrast, pneumatic systems use compressed air or gas to achieve mechanical motion. Since air is compressible, pneumatic systems tend to be faster but less powerful than hydraulic ones. The choice between hydraulic vs pneumatic often depends on the required output and control needed for a specific task.

System Components

Both systems consist of similar functional components—pumps/compressors, valves, actuators, and reservoirs/tanks—but differ in design and materials. Hydraulic systems include fluid reservoirs, pumps, and precise valves to manage high-pressure oil flow. Pneumatic systems use air compressors, storage tanks, and simpler valve designs. These differences influence performance, complexity, and maintenance needs.

Power and Performance Comparison

Force Output and Precision

Hydraulic systems excel in delivering high force and accurate control, making them ideal for heavy-duty applications such as construction machinery, aircraft landing gear, and industrial presses. They maintain consistent pressure without losing energy, allowing for smooth, powerful movement. Pneumatic systems, while less powerful, offer quick response times and are suitable for tasks requiring repetitive motion, such as assembly lines and packaging machines.

Speed and Responsiveness

Pneumatic systems generally operate faster than hydraulic systems due to the compressibility of air, which allows for rapid actuation. However, this same property can reduce precision and stability under load. Hydraulic systems, while slower, provide superior control and consistency, especially in applications where exact positioning and sustained force are critical.

Efficiency and Maintenance Considerations

Energy Efficiency

Hydraulic systems are more energy-efficient when handling high-force tasks because they lose minimal energy during operation. However, maintaining proper fluid levels and preventing leaks is crucial to preserving efficiency. Pneumatic systems require continuous air compression, which can lead to higher energy consumption over time, particularly in large-scale operations.

Maintenance Requirements

- Hydraulic systems need regular maintenance to check for fluid contamination, leaks, and component wear.

- Pneumatic systems are simpler and easier to maintain, with fewer components prone to failure.

Leaks in hydraulic systems can cause environmental hazards and costly downtime, whereas pneumatic leaks are less harmful but may still affect system performance if not addressed promptly.

Cost and Environmental Impact

Initial Investment and Long-Term Costs

Hydraulic systems typically have higher upfront costs due to complex components and specialized fluids. However, their durability and efficiency can result in lower long-term operating costs for heavy-use applications. Pneumatic systems are usually cheaper to install and operate, making them a popular choice for smaller or medium-scale operations.

Environmental Concerns

Hydraulic systems pose environmental risks from potential fluid leaks, which can contaminate soil and water sources. Proper disposal of used hydraulic fluids is also necessary to comply with environmental regulations. Pneumatic systems are cleaner, using only compressed air, which eliminates the risk of hazardous spills and makes them preferable in sensitive environments like food processing and pharmaceuticals.

Applications Across Industries

Where Each System Excels

Hydraulic systems are commonly found in:

- Construction equipment (excavators, bulldozers)

- Aerospace (landing gear, flight controls)

- Heavy manufacturing (presses, lifts)

Pneumatic systems dominate in:

- Automated production lines

- Food and beverage packaging

- Medical devices and cleanroom environments

The choice between hydraulic vs pneumatic systems ultimately depends on the operational demands, such as required force, speed, cleanliness, and budget constraints.

Conclusion

Choosing between hydraulic and pneumatic systems involves evaluating several factors, including power requirements, efficiency, maintenance, cost, and environmental impact. While hydraulic systems deliver unmatched force and precision, they come with higher complexity and maintenance needs. Pneumatic systems offer simplicity, speed, and cleanliness at a lower cost but lack the raw power of hydraulics. By understanding the strengths and weaknesses of each, you can make an informed decision that aligns with your operational goals.

Frequently Asked Questions (FAQ)

What is the main difference between hydraulic and pneumatic systems?

The primary difference lies in the medium used to transmit power. Hydraulic systems use incompressible liquids (usually oil), while pneumatic systems use compressed air or gas. This affects their power output, speed, and suitability for different applications.

Which system is better for heavy lifting?

Hydraulic systems are better suited for heavy lifting due to their ability to generate high force with precise control. They are commonly used in cranes, excavators, and industrial presses.

Are pneumatic systems safer than hydraulic systems?

In general, yes. Pneumatic systems use air, so there's no risk of hazardous fluid leaks. This makes them safer in environments where cleanliness and safety are priorities, such as food processing and healthcare facilities.

Can I upgrade from a pneumatic to a hydraulic system?

Yes, but it requires significant changes to the system design, including adding fluid reservoirs, pumps, and reinforced components. It’s important to assess whether the increased power justifies the added cost and complexity.

Looking for expert advice?

If you’re unsure which system is right for your operation, our team can help. Whether you need assistance with hydraulic vs pneumatic cylinder selection or complete system integration, we offer tailored solutions for industrial automation, maintenance, and optimization. Contact us today to learn more about how we can support your business needs.