Relés de control para equipos de control de motores: rendimiento y seguridad óptimos

En el mundo de los equipos de control de motores, los relés de control desempeñan un papel crucial para garantizar un rendimiento y una seguridad óptimos. Comprender su función e importancia es fundamental para cualquier persona que trabaje con estos equipos. Además, saber cómo lograr un rendimiento óptimo, considerar las consideraciones de seguridad, seleccionar el relé de control adecuado y mantenerse al día con las tendencias futuras puede mejorar considerablemente la eficiencia y la durabilidad de los sistemas de control de motores.

Comprensión de los relés de control

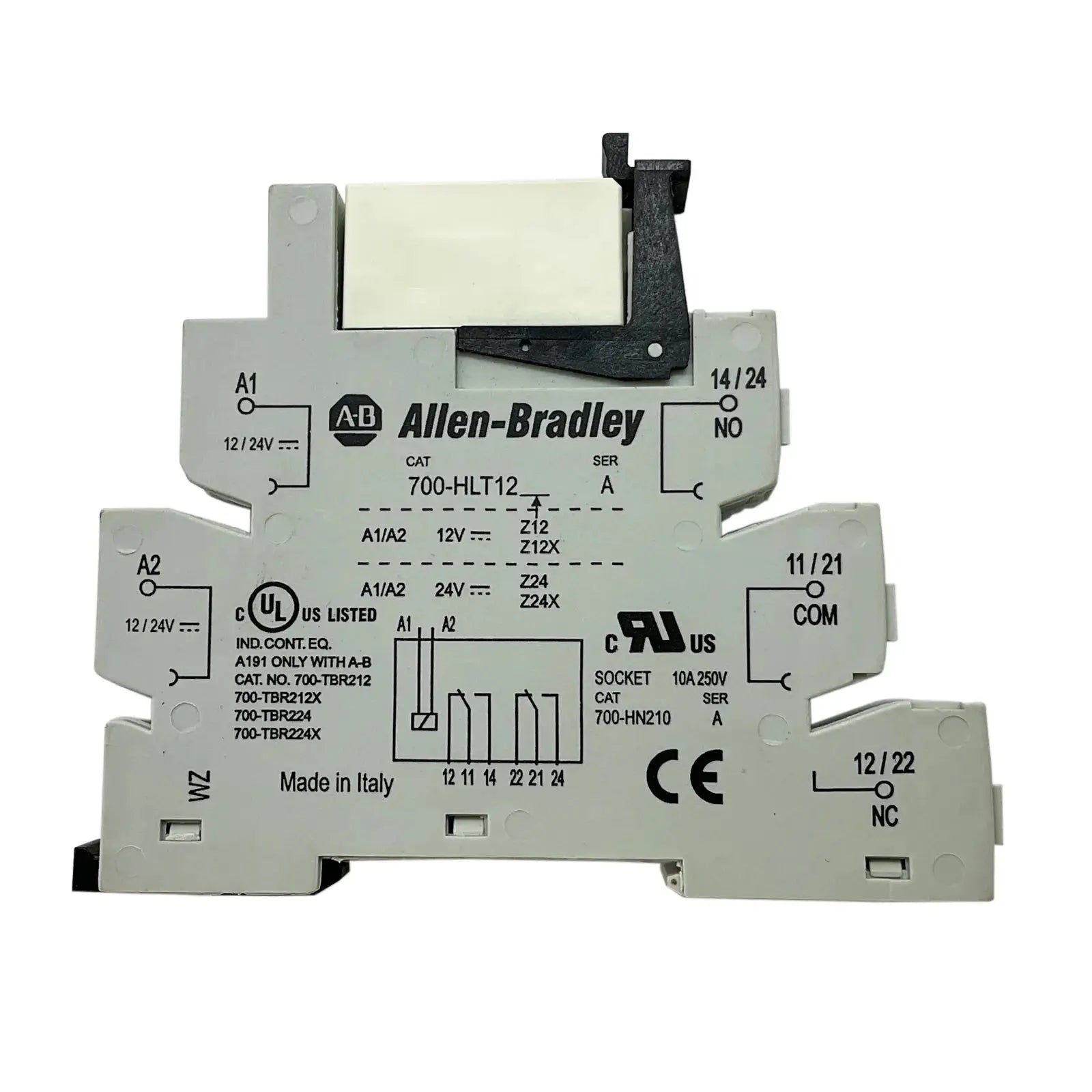

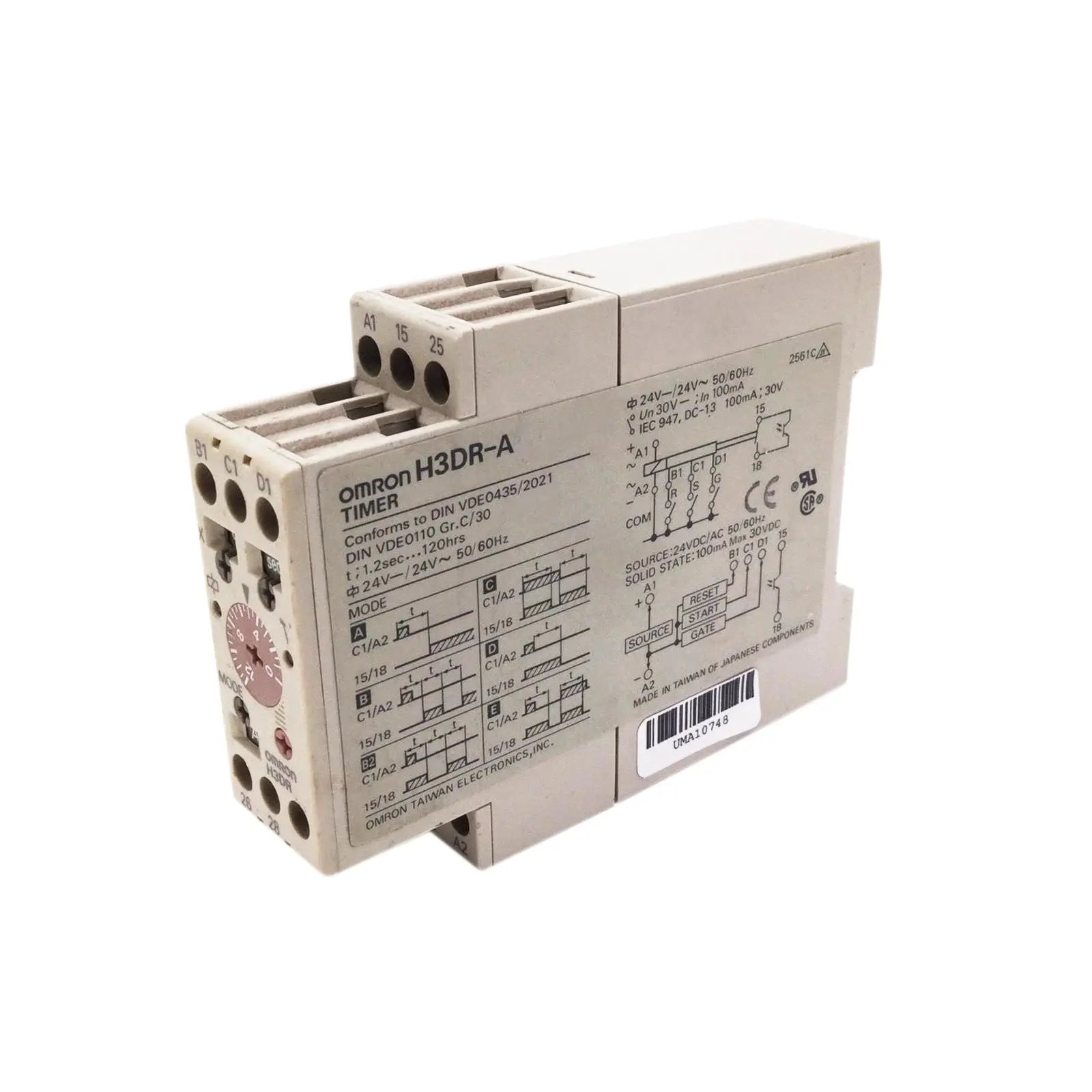

Los relés de control son dispositivos electromecánicos que actúan como interruptores en los circuitos de control de motores. Son responsables de controlar el flujo de corriente eléctrica a diversos componentes, como motores, solenoides y contactores. Al monitorear parámetros específicos y responder en consecuencia, los relés de control permiten un control preciso de los equipos accionados por motor.

Definición y función de los relés de control

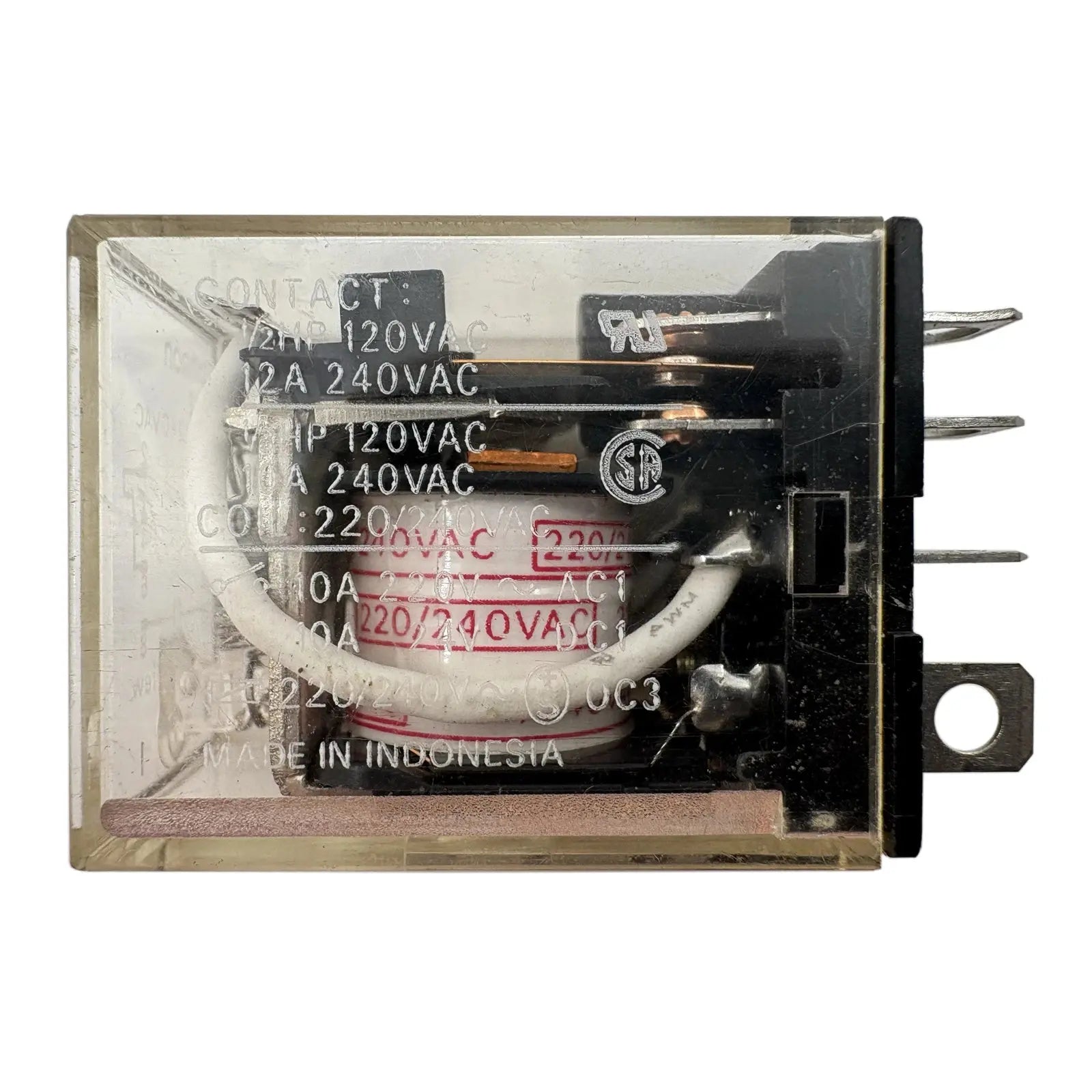

Un relé de control es un interruptor eléctrico que funciona según la entrada recibida de otros equipos. Consiste en una bobina electromagnética y uno o más conjuntos de contactos. Al activarse, la bobina genera un campo magnético que une los contactos, permitiendo el flujo de corriente. Este mecanismo permite a los relés de control conmutar entre diferentes circuitos eléctricos, controlando el funcionamiento de motores y otros dispositivos.

Importancia de los relés de control en los equipos de control de motores

Los relés de control son vitales para los equipos de control de motores debido a su capacidad para manejar altas corrientes, aislar circuitos y proporcionar un funcionamiento fiable. Sirven como interfaz entre el sistema de control y el motor, lo que permite un control seguro y eficiente. Sin relés de control, el funcionamiento de los motores y otros componentes sería complejo, inutilizando todo el sistema de control del motor.

Una de las principales ventajas de los relés de control es su capacidad para manejar grandes corrientes. Esto los hace ideales para controlar motores, que suelen requerir altos niveles de potencia eléctrica. Al gestionar eficazmente el flujo de corriente, los relés de control evitan daños al motor y garantizan su correcto funcionamiento.

Además de su capacidad para manejar corriente, los relés de control también desempeñan un papel crucial en el aislamiento de circuitos. Esto significa que pueden separar diferentes circuitos eléctricos, evitando interferencias y garantizando que cada componente funcione de forma independiente. Al proporcionar este nivel de aislamiento, los relés de control mejoran la fiabilidad y la seguridad general de los equipos de control de motores.

Además, los relés de control ofrecen un funcionamiento fiable, lo que los convierte en la opción preferida en diversas industrias. Su diseño electromecánico permite un rendimiento constante, incluso en entornos hostiles. Esta fiabilidad es crucial en aplicaciones de control de motores, donde cualquier fallo o mal funcionamiento puede provocar costosos tiempos de inactividad y posibles riesgos de seguridad.

En conclusión, los relés de control son componentes esenciales en los circuitos de control de motores. Su capacidad para manejar altas corrientes, aislar circuitos y proporcionar un funcionamiento fiable los hace indispensables para un control preciso de los equipos accionados por motor. Sin ellos, el funcionamiento eficiente de los motores y otros componentes se vería comprometido, lo que resalta la importancia de estos dispositivos electromecánicos en el campo del control de motores.

Cómo lograr un rendimiento óptimo con relés de control

Para garantizar el mejor rendimiento de los equipos de control de motores, se deben considerar varios factores clave. El mantenimiento regular y el cumplimiento de las prácticas recomendadas pueden prolongar significativamente la vida útil de los relés de control y otros componentes del sistema. Además, es crucial comprender la función de los relés de control para mantener un rendimiento óptimo.

Factores clave para un rendimiento óptimo

Una instalación y un cableado adecuados son fundamentales para lograr un rendimiento óptimo de los relés de control. Seguir las instrucciones del fabricante y las normas del sector puede evitar problemas causados por conexiones incorrectas. También es importante seleccionar relés de control adecuados para la aplicación específica, teniendo en cuenta factores como el voltaje, la corriente y las condiciones ambientales.

Consejos de mantenimiento para relés de control

El mantenimiento regular es esencial para mantener los relés de control en óptimas condiciones. Se recomienda inspeccionar para detectar sobrecalentamiento, verificar conexiones sueltas y limpiar los contactos. Además, reemplazar rápidamente los relés o componentes desgastados puede prevenir posibles fallas y tiempos de inactividad del sistema. Implementar un programa de mantenimiento preventivo y documentar las actividades de mantenimiento puede garantizar la confiabilidad a largo plazo de los relés de control.

Un aspecto importante a considerar para lograr un rendimiento óptimo con los relés de control es el uso de dispositivos de protección. Estos dispositivos, como fusibles e interruptores automáticos, están diseñados para proteger los relés de control y todo el sistema contra fallos eléctricos y sobrecargas. Al incorporar dispositivos de protección al circuito, se minimiza el riesgo de daños en los relés de control debido a corrientes excesivas o cortocircuitos. Es crucial seleccionar los dispositivos de protección adecuados según los requisitos específicos del sistema, garantizando que sean capaces de interrumpir la corriente de fallo en un plazo seguro y aceptable.

Otro factor que puede afectar considerablemente el rendimiento de los relés de control es la calidad de la fuente de alimentación. Las fluctuaciones de voltaje o frecuencia pueden provocar un comportamiento errático de los relés de control, lo que resulta en un funcionamiento inestable y posibles daños. Para mitigar esto, se recomienda utilizar reguladores de voltaje o acondicionadores de potencia para estabilizar la fuente de alimentación. Estos dispositivos ayudan a mantener un voltaje y una frecuencia constantes, garantizando que los relés de control reciban una fuente de alimentación limpia y estable.

Consideraciones de seguridad para el uso de relés de control

Si bien los relés de control son vitales para los equipos de control de motores, es crucial comprender los riesgos potenciales y tomar las precauciones necesarias para garantizar la seguridad. Al cumplir las normas y regulaciones de seguridad y conocer los riesgos comunes, los operadores pueden minimizar el riesgo de accidentes y lesiones.

Riesgos potenciales y cómo evitarlos

Los relés de control manejan altas corrientes, lo que puede suponer riesgos como descargas eléctricas e incendios. Garantizar un aislamiento adecuado, utilizar equipos de protección e implementar enclavamientos de seguridad puede ayudar a mitigar estos riesgos. Las inspecciones y pruebas periódicas permiten identificar posibles problemas antes de que se conviertan en problemas de seguridad graves.

Normas y reglamentos de seguridad

El cumplimiento de las normas y regulaciones de seguridad es crucial al utilizar relés de control. Familiarícese con las normas pertinentes, como las establecidas por la Administración de Seguridad y Salud Ocupacional (OSHA) y el Código Eléctrico Nacional (NEC), para garantizar que sus equipos de control de motores cumplan plenamente con las normas. Revisar y actualizar periódicamente sus protocolos de seguridad puede ayudar a minimizar los riesgos y a mantener un entorno de trabajo seguro.

Además, es importante considerar los factores ambientales que pueden afectar el funcionamiento seguro de los relés de control. Las temperaturas extremas, la humedad y las sustancias corrosivas pueden afectar el rendimiento y la vida útil de los relés. Por lo tanto, es fundamental instalar los relés de control en gabinetes o envolventes adecuados que proporcionen la protección adecuada contra estos elementos.

Además, la capacitación y la formación adecuadas son vitales para quienes trabajan con relés de control. Los operadores deben recibir capacitación sobre el manejo y la operación seguros de los relés, así como sobre los procedimientos correctos para la resolución de problemas y el mantenimiento. Los cursos y talleres de actualización periódicos pueden ayudar a reforzar los conocimientos y mantener a los operadores al día con las últimas prácticas de seguridad.

Cómo seleccionar el relé de control adecuado para su equipo

Elegir el relé de control adecuado es crucial para el rendimiento general y la fiabilidad de los equipos de control de motores. Un relé de control actúa como el "cerebro" del equipo, garantizando que se envíen las señales correctas para activar o desactivar los distintos componentes. Sin un relé de control adecuado, el equipo podría no funcionar de forma óptima o incluso presentar fallos de funcionamiento.

Al seleccionar un relé de control, hay varias consideraciones importantes a tener en cuenta. En primer lugar, debe evaluar los requisitos de carga de su equipo. Esto incluye factores como la tensión y la corriente nominales que el relé de control debe manejar. Elegir un relé de control con capacidad insuficiente puede provocar sobrecalentamiento y fallos prematuros, mientras que seleccionar uno demasiado potente puede generar costos innecesarios.

Además de los requisitos de carga, es fundamental considerar las condiciones ambientales en las que funcionará el relé de control. Por ejemplo, si su equipo está expuesto a temperaturas extremas o altos niveles de humedad, deberá elegir un relé de control diseñado específicamente para soportar estas condiciones. Descuidar este aspecto puede provocar fallos prematuros y reparaciones costosas.

Otro factor crucial a considerar es la fiabilidad y reputación del fabricante del relé de control. Optar por una marca consolidada y de buena reputación garantiza la adquisición de un producto de alta calidad, rigurosamente probado y con un rendimiento fiable. Merece la pena invertir en un relé de control de un fabricante de confianza para evitar posibles problemas y garantizar la satisfacción a largo plazo.

Si bien es importante considerar estos factores, es igualmente crucial conocer los errores comunes que deben evitarse al seleccionar relés de control. Un error común es el dimensionamiento inadecuado, donde el relé de control elegido es demasiado pequeño o demasiado grande para los requisitos del equipo. Esto puede provocar un funcionamiento ineficiente, un mayor consumo de energía y posibles daños al equipo.

Otro error que se debe evitar es no tener en cuenta los requisitos de voltaje y corriente del equipo. Es fundamental elegir un relé de control que se ajuste a las especificaciones de voltaje y corriente para garantizar un funcionamiento correcto y evitar problemas eléctricos.

Por último, otro error común es no considerar los factores ambientales que pueden afectar el rendimiento del relé. Por ejemplo, si su equipo está ubicado en un entorno polvoriento o corrosivo, debe seleccionar un relé de control con la protección adecuada contra estos elementos. Ignorar estos factores puede provocar fallos prematuros y costosos tiempos de inactividad.

Al considerar los requisitos de carga, las condiciones ambientales y la reputación del fabricante, podrá tomar una decisión informada al seleccionar un relé de control. Evitar errores comunes, como dimensionar incorrectamente, ignorar los requisitos de voltaje y corriente, y no considerar los factores ambientales, le ayudará a ahorrar tiempo, dinero y posibles problemas en el futuro.

Tendencias futuras en la tecnología de relés de control

A medida que la tecnología avanza, los diseños de relés de control evolucionan para satisfacer las demandas de los sistemas modernos de control de motores. Mantenerse informado sobre las tecnologías e innovaciones emergentes puede ayudarle a garantizar que sus equipos de control de motores se mantengan actualizados y eficientes.

Innovaciones en el diseño de relés de control

Los nuevos diseños de relés de control se centran en mejorar la fiabilidad, reducir el consumo energético y aumentar la funcionalidad. Los relés inteligentes que incorporan protocolos de comunicación avanzados y funciones de lógica programable son cada vez más populares, lo que permite un control y diagnóstico de motores más eficiente.

Impacto de las tecnologías emergentes en los relés de control

Las tecnologías emergentes, como el Internet de las Cosas (IoT) y la inteligencia artificial, están teniendo un impacto significativo en los relés de control. Las funciones de conectividad permiten la monitorización y el control remotos, mientras que los algoritmos de IA pueden optimizar el consumo de energía y predecir las necesidades de mantenimiento. Mantenerse al día con estas tecnologías puede proporcionar información valiosa sobre el futuro de los equipos de control de motores.

En conclusión, los relés de control son componentes clave en los equipos de control de motores, desempeñando un papel crucial para lograr un rendimiento óptimo y garantizar la seguridad. Comprender su función, seleccionar el relé de control adecuado y mantenerse al día con las tendencias futuras es esencial para cualquier persona involucrada en el diseño, la instalación o el mantenimiento de sistemas de control de motores. Al priorizar el rendimiento y la seguridad, e incorporar los avances tecnológicos, los equipos de control de motores pueden operar con la máxima eficiencia, lo que beneficia a numerosas industrias que dependen del control preciso de los motores eléctricos.

¿Necesita pedidos al por mayor o recomendaciones de expertos sobre MCE-B-CR?

¿Busca pedidos al por mayor de MCE-B-CR o necesita ayuda para elegir la solución industrial adecuada? Nuestro equipo está aquí para ayudarle con presupuestos personalizados, recomendaciones de productos y asesoramiento técnico. Ya sea electricista, contratista o empresario, ofrecemos soluciones a medida para satisfacer sus necesidades.

📩 ¡ Contáctanos o chatea con nosotros en vivo para obtener asistencia instantánea!

¡Explora nuestra colección de ofertas de locura mensual!

¡No te pierdas los grandes ahorros en nuestra tienda! Descubre las mejores ofertas en:

¡Explora estas categorías ahora y aprovecha las mejores ofertas antes de que se acaben!