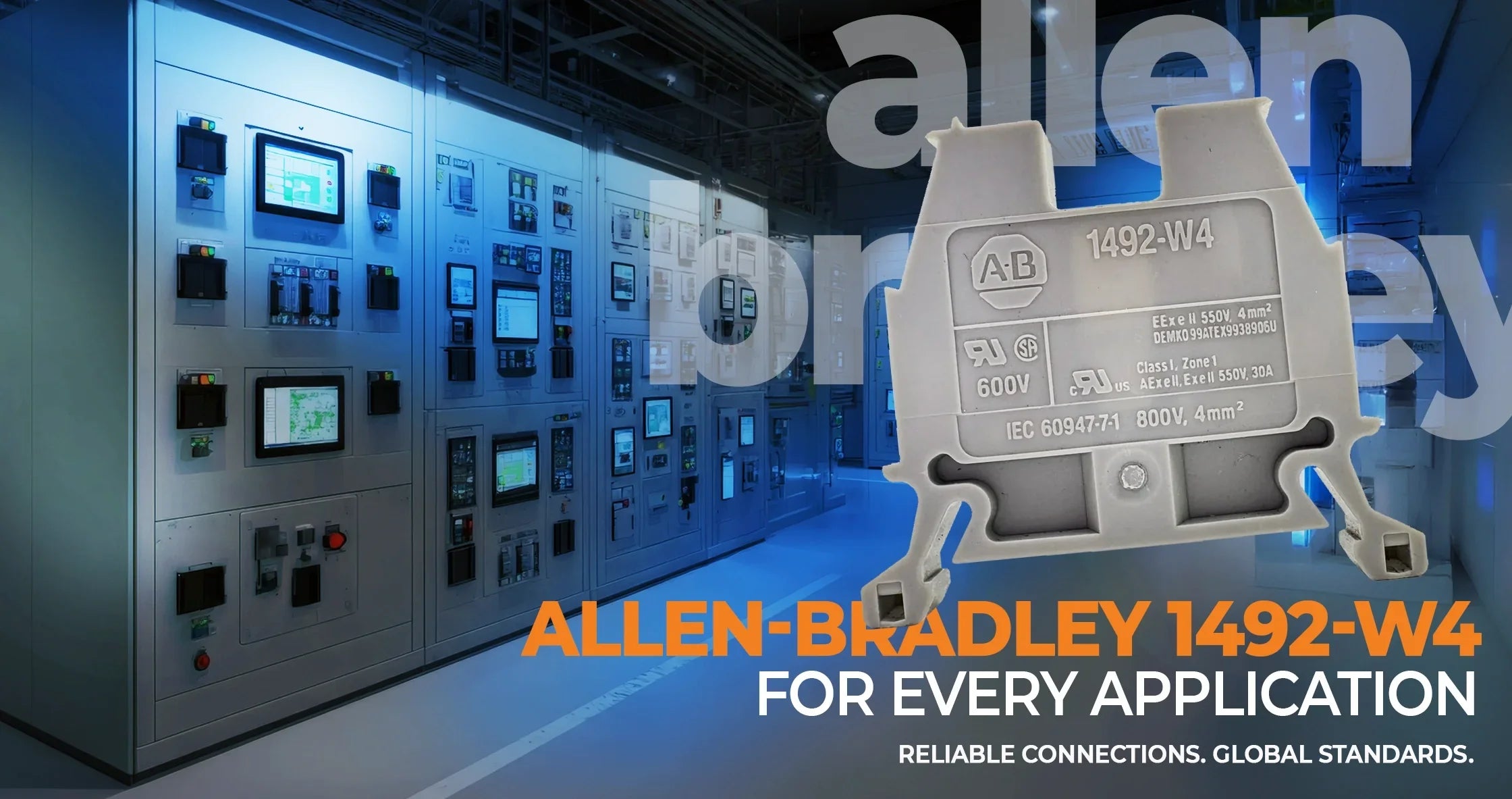

The Allen-Bradley 1492-W4 Terminal Block is one of the most trusted components in industrial automation, power distribution, and control system wiring. Designed for high performance, safety, and compliance with international standards, this terminal block provides secure, reliable connections that engineers and electricians depend on daily. In this comprehensive guide, we will explore its detailed specifications, the importance of each parameter, best practices for installation, application examples across industries, and why it remains a leading choice in industrial wiring solutions.

What is the Allen-Bradley 1492-W4 Terminal Block?

The Allen-Bradley 1492-W4 Terminal Block is a single-circuit feed-through block that mounts on a DIN rail terminal block. It is built for organizing, connecting, and managing conductors safely in control panels, enclosures, and industrial systems. Rated at 30A/600V (UL/CSA) and 32A/800V (IEC), this terminal block combines durability and versatility, making it suitable for both control and power wiring.

Unlike soldered or crimp-only connections, terminal blocks like the 1492-W4 provide modularity, easy maintenance, and reconfiguration without specialized tools. This makes them the backbone of modern panel design.

Detailed Specifications of the Allen-Bradley 1492-W4 Terminal Block

The datasheet provides an in-depth look at the specifications that define its performance:

Rated Current: 30 A (UL/CSA) and 32 A (IEC)

This terminal block carries up to 30 amps at 600V (UL/CSA) and 32 amps at 800V (IEC).

● Why it matters: Ensures safe operation under heavy loads such as motor circuits or branch feeders. High current capacity prevents overheating and extends component life.

Rated Voltage: 600 V / 800 V

● 600 V AC/DC for North America (UL/CSA)

● 800 V AC/DC under IEC standards

● Why it matters: Voltage rating ensures insulation safety and dielectric strength, reducing the risk of arcing or breakdown in high-voltage environments.

Conductor Size Range: 22–10 AWG (0.5–4 mm²)

Supports both small control wires and medium power conductors.

● Why it matters: Allows flexibility in wiring. One block type can be used across signal, control, and power circuits.

Wire Strip Length: 9 mm

Stripping insulation to exactly 9 mm ensures the correct contact surface.

● Why it matters: Too little strip length causes poor connection; too much exposes bare conductor, risking shorts.

Tightening Torque: 0.6 N·m

Screw clamping torque ensures consistent connection pressure.

● Why it matters: Prevents loose wires in high-vibration environments. Over-tightening risks damaging conductors.

Housing and Construction

● Polyamide 6.6 housing, UL94 V-0 self-extinguishing

● Tin-plated copper alloy current bar for conductivity

● Temperature range: -40 °C to +90 °C

● Why it matters: Ensures safe use in harsh industrial conditions, resistant to heat, fire, and chemicals.

Dimensions

● Width: ~6 mm

● Height: ~45 mm

● Depth: ~35 mm

● Why it matters: Narrow width conserves DIN rail space, allowing dense wiring in compact panels.

Safety and Modularity Features

● Finger-safe housing prevents accidental contact.

● Bridging options for linking adjacent terminals.

● DIN-rail mounting ensures easy installation and replacement.

● Why it matters: Enhances safety while enabling modular, expandable wiring systems.

Why Each Specification Matters

Every rating of the Allen-Bradley 1492-W4 Terminal Block ensures reliability and compliance:

● Current capacity guarantees circuits won’t overheat.

● Voltage rating protects against insulation breakdown.

● Wire size range reduces need for multiple block types.

● Material properties provide fire resistance and durability.

● Torque and strip length ensure mechanical and electrical reliability.

● Finger-safe features reduce workplace accidents.

Industry Applications of the Allen-Bradley 1492-W4 Terminal Block

1. Control Panels and PLC Systems

The 1492-W4 simplifies field wiring to programmable logic controllers (PLCs), neatly organizing sensor and actuator connections.

2. Power Distribution

Handles branch wiring in distribution boxes and motor control centers, bridging feeders and loads safely.

3. Industrial Machinery

Used in conveyors, CNC machines, and packaging systems, ensuring organized wiring for motors, sensors, and relays.

4. Building Automation

Supports HVAC, lighting, and access control systems, offering easy maintenance in facility management.

5. Energy & Utilities

Applied in substations, renewable energy plants, and monitoring panels where safe connections are critical.

6. Transportation & Rail

Chosen for signaling systems and rolling stock wiring, thanks to vibration resistance and compliance.

7. Oil, Gas, and Hazardous Environments

Used in certified enclosures for chemical plants, refineries, and offshore platforms.

Benefits of Using the Allen-Bradley 1492-W4 Terminal Block

● Reliability: Meets UL, CSA, CE, and IEC certifications.

● Safety: Finger-safe, flame-retardant housing reduces hazards.

● Versatility: Supports global wiring standards.

● Space-saving: Compact size maximizes DIN rail usage.

● Ease of Maintenance: Allows reconfiguration without rewiring entire systems.

● Cost-effectiveness: Reduces downtime and wiring errors.

Best Practices for Installation

- Strip wires to 9 mm for optimal contact.

- Use ferrules for stranded conductors.

- Tighten screws to 0.6 N·m torque to ensure secure clamping.

- Group and color code blocks by circuit function.

- Label terminals for quick troubleshooting.

- Use jumpers for common supply rails.

Comparison with Related Allen-Bradley Terminal Blocks

● 1492-W3: Smaller, for 2.5 mm² wires, lower current.

● 1492-W6: For 6 mm² wires, higher current capacity.

● 1492-J Series: Spring-clamp type for tool-free connections.

● Why 1492-W4? It balances compact size with sufficient current and voltage capacity for most applications.

Troubleshooting & Maintenance Tips

● Loose Connections: Check torque and retighten periodically.

● Overheating: Ensure current is within rated limits.

● Corrosion: Use tin-plated versions in humid environments.

● Wire Damage: Always use the recommended strip length and ferrules.

Frequently Asked Questions (FAQ)

Q1: Can I use the 1492-W4 for DC circuits?

Yes, it supports both AC and DC at rated voltages.

Q2: What accessories are available?

Jumpers, end covers, end clamps, and marking tags.

Q3: Can stranded wires be used?

Yes, but ferrules are recommended for reliability.

Q4: Is it vibration-resistant?

Yes, with proper torqueing it withstands industrial vibrations.

Q5: What certifications does it carry?

UL Recognized, CSA Certified, CE Marked, and IEC compliant.

Conclusion

The Allen-Bradley 1492-W4 Terminal Block is more than just a connector—it’s a backbone of reliable electrical infrastructure. With its high current capacity, dual-standard voltage rating, and space-saving design, it serves industries ranging from manufacturing to energy and transportation. Its modularity, safety, and compliance make it an indispensable component in control panels worldwide.

For engineers, electricians, and panel builders seeking reliability and efficiency, the Allen-Bradley 1492-W4 Terminal Block remains a trusted solution. Learn more about its features and explore detailed product information by visiting the official Allen-Bradley 1492-W4 Terminal Block product page.

Related Product Collections You May Also Like

Explore a wide selection of contactors, relays, motor control gear, and automation components designed to work seamlessly with terminal blocks in control panel applications.

🔧 Electrical, Power & Plumbing →

Find power distribution equipment, surge protectors, and panel wiring accessories essential for safe and efficient electrical infrastructure.

Browse tools and hardware for electrical installation and maintenance, including ferrule crimpers, torque screwdrivers, and wire strippers perfect for terminal block setups.