Introduction

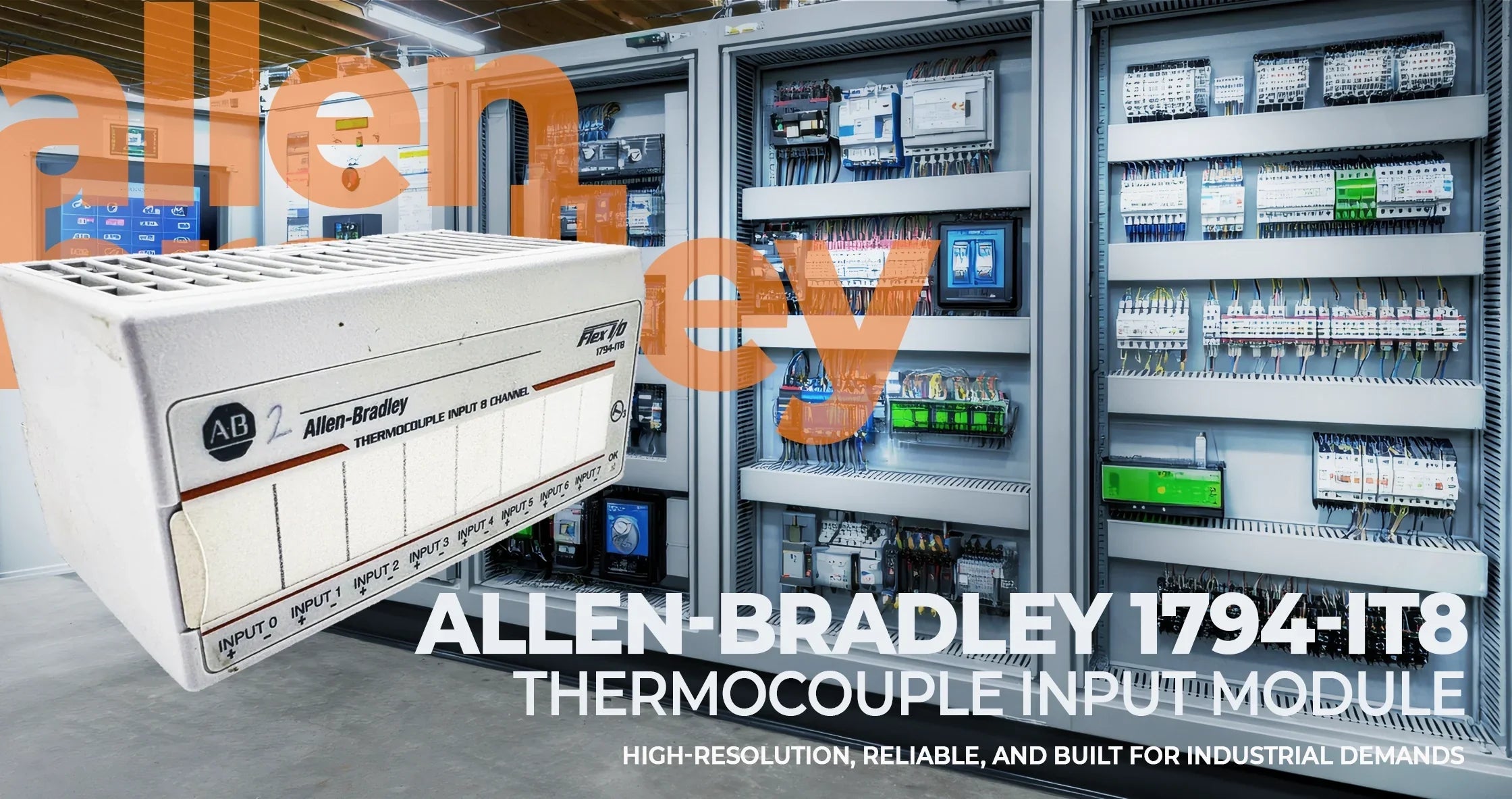

Industrial automation thrives on precise data acquisition and control. Among the most critical parameters to measure in process industries is temperature. The Allen-Bradley 1794-IT8 Thermocouple Input Module is a specialized FLEX I/O system module designed to handle this task with accuracy, reliability, and adaptability. With eight differential input channels, broad thermocouple compatibility, and robust noise immunity, the 1794-IT8 has become a staple in industries where precise temperature monitoring makes the difference between safety and disaster, efficiency and waste, or quality and rejection.

In this expanded blog, we will explore every aspect of the Allen-Bradley 1794-IT8 Thermocouple Input Module, from detailed specifications and why they matter, to installation procedures, certifications, applications across industries, and compatibility with accessories. You’ll also discover real-world case studies, installation walkthroughs, and best practices that bring this powerful module to life.

What is the Allen-Bradley 1794-IT8 Thermocouple Input Module?

The Allen-Bradley 1794-IT8 Thermocouple Input Module belongs to Rockwell Automation’s FLEX I/O system, a modular I/O platform that allows users to tailor I/O setups based on their application. FLEX I/O modules are compact, cost-effective, and highly versatile, making them widely used in distributed control systems.

This particular model specializes in thermocouple and millivolt input signals, providing eight high-resolution channels with integrated cold junction compensation when used with compatible bases. This means plant engineers can connect thermocouples directly, saving time and avoiding the need for external signal conditioning.

Detailed Specifications and Their Importance

1. Number of Inputs: 8 Differential Channels

The module supports eight differential inputs, meaning each channel reads a pair of wires (positive and negative). Differential measurement cancels out electrical noise common to both leads, ensuring accurate readings even in electrically noisy environments such as motor-driven plants.

Why it matters: Industrial plants often require monitoring multiple points—ovens, furnaces, reactors, or storage tanks. The ability to connect eight sensors reduces cost per point and simplifies wiring.

2. Input Voltage Range: –76.5 mV to +76.5 mV

Thermocouples generate tiny voltages when heated. The ±76.5 mV range covers the outputs of all common thermocouple types (J, K, T, E, R, S, etc.).

Why it matters: This wide range ensures universal compatibility. Engineers don’t have to worry whether a sensor exceeds module limits, and they can mix thermocouple types across different channels if needed.

3. Resolution: 16 Bits (≈2.384 μV per step)

The high-resolution ADC provides fine measurement detail. For example, a K-type thermocouple changes ~41 μV per °C. With a 2.384 μV resolution, the module detects temperature changes as small as ~0.06 °C.

Why it matters: In precision processes like pharmaceutical sterilization or semiconductor manufacturing, small deviations in temperature can lead to wasted batches. High resolution ensures precise control.

4. Data Format: 16-bit Two’s Complement or Offset Binary

Users can configure data to suit their PLC or SCADA system. Two’s complement handles signed values, while offset binary provides unipolar readings.

Why it matters: Flexibility in data formatting allows smoother integration with different controllers without requiring complex conversions.

5. Channel Bandwidth: 0–2.62 Hz (-3 dB)

The input filter allows only low-frequency signals to pass, cutting out electrical noise.

Why it matters: Temperature changes are inherently slow, so filtering out high-frequency noise (like 50/60 Hz interference) results in smoother, more reliable readings.

6. Conversion Time: ~325 ms per channel (2.6 seconds for all 8)

While slower than other analog inputs, this rate is ideal for thermal monitoring.

Why it matters: A reactor doesn’t change temperature in milliseconds. Slow conversion minimizes noise while providing sufficiently frequent updates for control.

7. Isolation Voltage: 850 V DC for 1 second

The module isolates input and logic power domains.

Why it matters: Isolation protects expensive controllers and ensures operator safety, even if a thermocouple wire accidentally touches high voltage.

8. Environmental Ratings

● Temperature: –20 °C to +55 °C

● Humidity: 5–95% non-condensing

● Vibration: up to 5 g @ 10–500 Hz

Why it matters: The Allen-Bradley 1794-IT8 Thermocouple Input Module is built for harsh industrial environments where conditions fluctuate.

Installation and Wiring Guide

Choosing the Right Terminal Base

The module requires a terminal base for installation. Options include:

● 1794-TB2 and 1794-TB3 – standard bases for millivolt signals.

● 1794-TB3T – specialized base for thermocouples with Cold Junction Compensation (CJC).

Wiring Guidelines

- Connect each thermocouple’s positive lead to its assigned positive terminal.

- Connect each negative lead to the corresponding return terminal.

- Use shielded twisted-pair thermocouple cable to minimize EMI.

- Install CJC sensors in TB3T slots for accurate readings.

- Ensure the base keyswitch is set to position 3 before mounting.

Cold Junction Compensation

The TB3T includes slots for CJC sensors. These measure ambient temperature at the connection point and automatically correct thermocouple readings.

Why it matters: Without CJC, thermocouple readings would be inaccurate due to varying junction temperatures.

Certifications and Compliance

The Allen-Bradley 1794-IT8 Thermocouple Input Module meets international standards:

● UL & cULus Listed – safety and performance compliance.

● CE Marked – conforms to EU EMC/Low Voltage directives.

● CSA Certified – Canadian market compliance.

● ATEX & IECEx – safe for Zone 2 hazardous environments.

● SIL 2 (TÜV) – functional safety applications.

Industry Applications

1. Chemical Processing

Reactors and distillation columns require precise temperature control. The 1794-IT8 provides reliable readings that feed into distributed control systems.

2. Food & Beverage

Baking ovens, pasteurizers, and freezers rely on accurate thermal profiles to ensure safety and quality.

3. Pharmaceutical Manufacturing

Sterilization chambers and cleanroom environments demand sub-degree accuracy. The 1794-IT8 ensures compliance with regulatory standards.

4. Metals & Glass

High-temperature furnaces depend on continuous monitoring for both quality and safety.

5. Energy & Utilities

Boilers, turbines, and generators use thermocouples to maintain optimal operating conditions and efficiency.

Case Study: Chemical Reactor Monitoring

A large chemical plant integrated the Allen-Bradley 1794-IT8 Thermocouple Input Module into its distributed control system to monitor eight points on a catalytic reactor. Before installation, the plant suffered from inconsistent temperature data due to electrical noise. With the IT8’s differential inputs and filtering, noise interference dropped by 90%, improving process stability and reducing batch variability.

Compatible Accessories

● 1794-TB3T Base Unit – essential for thermocouples with CJC.

● Cold Junction Compensators – supplied with the module, required for accurate compensation.

● 1794-PS13 Power Supply – provides stable 24 V DC power.

● FLEX I/O Adapters – Ethernet/IP (1794-AENT) or DeviceNet adapters for communication.

Best Practices for Using the Allen-Bradley 1794-IT8 Thermocouple Input Module

- Always use proper grounding for shielded thermocouple cables.

- Avoid running thermocouple wiring parallel to high-voltage power lines.

- Regularly verify calibration and compensate for drift.

- Use proper terminal bases (TB3T with CJC for thermocouples).

- Leverage redundancy in critical applications (dual sensors per point).

Conclusion

The Allen-Bradley 1794-IT8 Thermocouple Input Module is a robust, versatile, and precise solution for industries requiring reliable temperature measurement. Its combination of high resolution, noise immunity, safety certifications, and compatibility with multiple thermocouple types makes it one of the most trusted modules in automation.

Whether you are working in chemical processing, pharmaceuticals, energy, or manufacturing, this module helps maintain process stability, safety, and efficiency. To explore its full capabilities and integration details, we recommend visiting the official product page of the Allen-Bradley 1794-IT8 Thermocouple Input Module.

Related Product Collections You May Be Interested In

Automation & PLC’s Collection →

Explore a wide range of programmable logic controllers (PLCs), input/output modules, and related automation equipment to build or expand your control system.

Motor Control Equipment Collection →

From contactors and starters to drives and overload relays, this collection provides essential motor control components for industrial automation.

Discover a variety of relays designed to handle industrial control switching needs, ensuring safety, reliability, and seamless integration into control panels.