Introduction

When it comes to reliable motor control in industrial applications, the Allen-Bradley 520F-DOT-A2L-A2L DOL Starter is a name that consistently stands out. This direct-on-line (DOL) starter combination integrates forward/reverse contactors, overload relays, and flexible torque handling, making it a top choice for engineers and facility managers who demand precision and durability. In this article, we will dive deep into its specifications, explore why each detail matters, and examine the industries where this product truly shines.

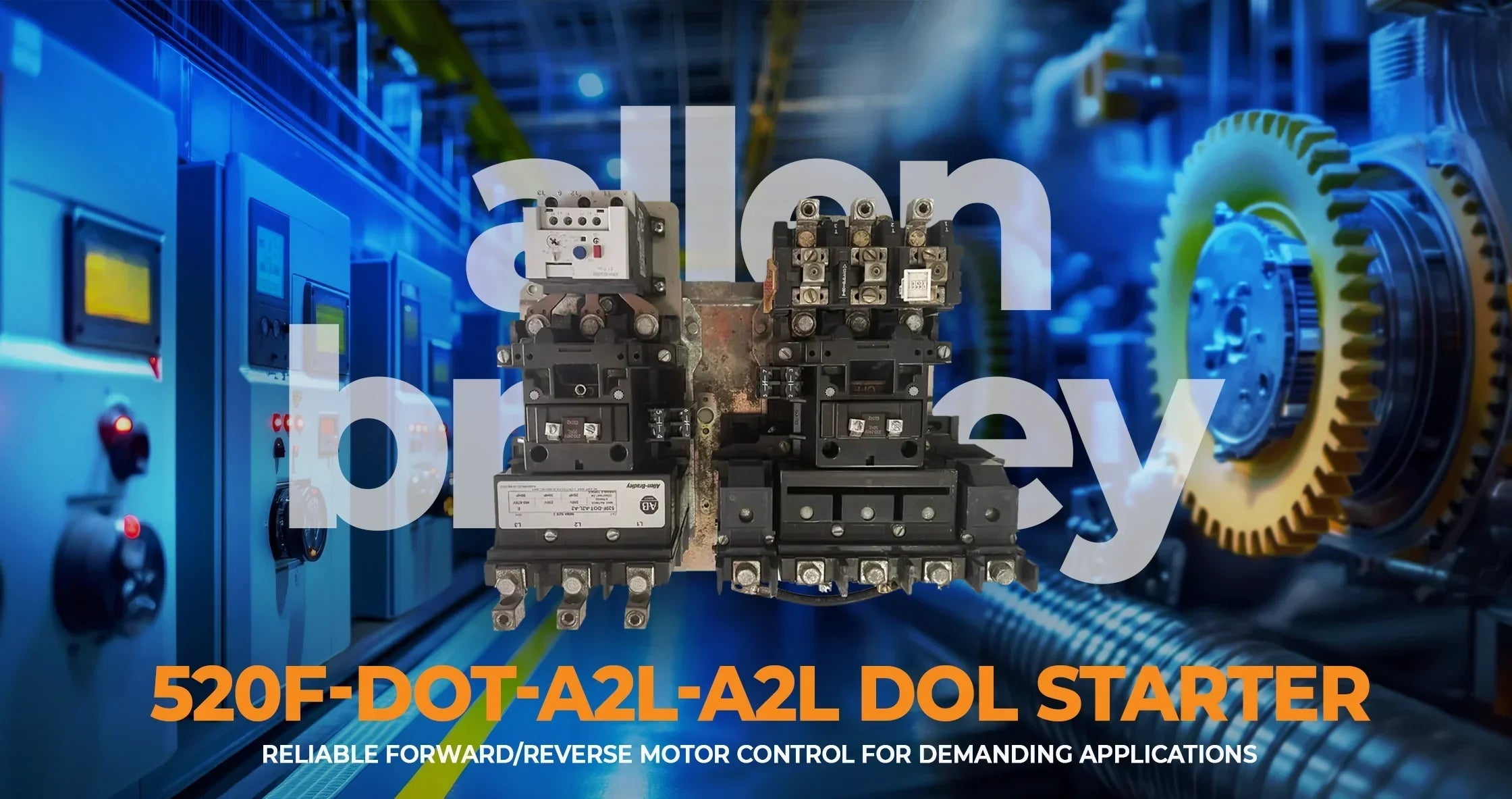

What is the Allen-Bradley 520F-DOT-A2L-A2L DOL Starter?

The Allen-Bradley 520F-DOT-A2L-A2L DOL Starter is a NEMA Size 3 forward/reverse two-speed starter designed for motors up to 90A continuous current. It features mechanical interlocks for safety, 115–120V AC coil operation, and both constant and variable torque compatibility. Being an open-style unit, it is designed for panel integration, offering engineers flexibility in control system design.

Key Specifications of the Allen-Bradley 520F-DOT-A2L-A2L DOL Starter

2-Speed (Consequent-Pole) Operation

The Allen-Bradley 520F-DOT-A2L-A2L DOL Starter is designed for two-speed motor applications. It can switch between low and high-speed windings, providing operators with flexibility in motor performance. This is particularly valuable in fans and pumps where different output levels are required.

Why It Matters: Two-speed starters help optimize energy use and extend motor life by running at lower speeds when full capacity isn’t necessary.

Forward/Reverse Contactor with Mechanical Interlock

This model includes forward and reverse contactors that allow motors to run in both directions. A mechanical interlock ensures that both directions cannot be engaged simultaneously, which would cause dangerous short circuits.

Why It Matters: Reversible operation is critical in conveyors, hoists, and cranes. The interlock ensures safety by preventing cross-engagement of contactors.

NEMA Size 3 (90A, up to 50 HP)

The Allen-Bradley 520F-DOT-A2L-A2L DOL Starter is a Size 3 starter, which corresponds to a 90A continuous current rating. This translates to roughly 25 HP at 200V, 30 HP at 230V, and 50 HP at 460/575V.

Why It Matters: NEMA sizing simplifies the selection process for engineers, ensuring compatibility between motor capacity and starter size.

Coil Voltage: 115–120V AC, 60Hz

The starter’s control coil is rated for 115–120V AC, 60Hz operation. This standard voltage is commonly found in North American industrial environments.

Why It Matters: Using a standard control voltage simplifies integration with existing control panels and systems.

Overload Relays (E1 Plus Solid-State)

This model uses Allen-Bradley E1 Plus solid-state overload relays, adjustable for 18–90A. These protect motors from sustained overcurrents.

Why It Matters: Overload relays are essential for preventing motor damage during abnormal operating conditions. Separate relays for each speed ensure tailored protection.

Constant or Variable Torque Support

The Allen-Bradley 520F-DOT-A2L-A2L DOL Starter can handle both constant torque (conveyors, hoists) and variable torque (fans, pumps) applications.

Why It Matters: This flexibility makes it suitable across a wide range of industries, reducing the need for multiple starter types.

Open Design

This model is an open-type unit, meaning it must be mounted inside a control panel or enclosure to meet environmental protection standards.

Why It Matters: Open designs offer flexibility for engineers designing custom panels and make maintenance more accessible.

Why Direct-On-Line (DOL) Starters Still Matter

The Allen-Bradley 520F-DOT-A2L-A2L DOL Starter is a direct-on-line starter, meaning the motor is connected directly to the supply voltage at startup. While this creates high inrush current, it provides maximum starting torque.

Why It Matters: In heavy-duty applications like conveyors and pumps, the ability to deliver immediate full torque is critical for efficient startup.

Applications of the Allen-Bradley 520F-DOT-A2L-A2L DOL Starter

Conveyor Systems

Conveyors in packaging, assembly, or material-handling operations often require reversible and multi-speed control. The Allen-Bradley 520F-DOT-A2L-A2L DOL Starter ensures safe forward/reverse operation with mechanical interlocks, making it perfect for this use case.

Pumps and Fans (HVAC & Process)

Industrial pumps and fans often need to operate at two speeds for energy savings. The starter’s overload protection and torque flexibility make it ideal for HVAC systems and process fans.

Hoists and Cranes

In lifting applications, reversing direction is essential. The Allen-Bradley 520F-DOT-A2L-A2L DOL Starter provides safe and reliable motor reversal for hoisting and crane operations.

Industrial Processing Plants

Chemical plants, water treatment facilities, and utilities benefit from this starter’s rugged design and flexibility, ensuring reliable performance in mission-critical systems.

Conclusion

The Allen-Bradley 520F-DOT-A2L-A2L DOL Starter combines robust motor protection, forward/reverse functionality, and two-speed flexibility into one compact design. Its compatibility with both constant and variable torque applications makes it one of the most versatile starters in industrial motor control. Whether you’re dealing with conveyors, pumps, or hoists, this product ensures both performance and safety.

For engineers and facility managers seeking more details or considering integration, you can learn more on the official product page.

Related Product Collections

To help you explore more, here are three related collections from Industrial Electrical Warehouse that complement the Allen-Bradley 520F-DOT-A2L-A2L DOL Starter:

Contactor & Overload Control Gear ➝

A comprehensive range of contactors and overloads designed for reliable motor control. This collection pairs perfectly with DOL starters for complete system solutions.

Explore a wide selection of motor starter assemblies, ideal for heavy-duty industrial applications and ensuring compatibility with various motor sizes.

Enhance your control systems with specialized relays that work alongside starters and contactors for advanced automation and safety.