Control Relays (Safety & Control Relays)

22 products

Showing 1 - 22 of 22 products

Control Relays – Safety & Control Solutions

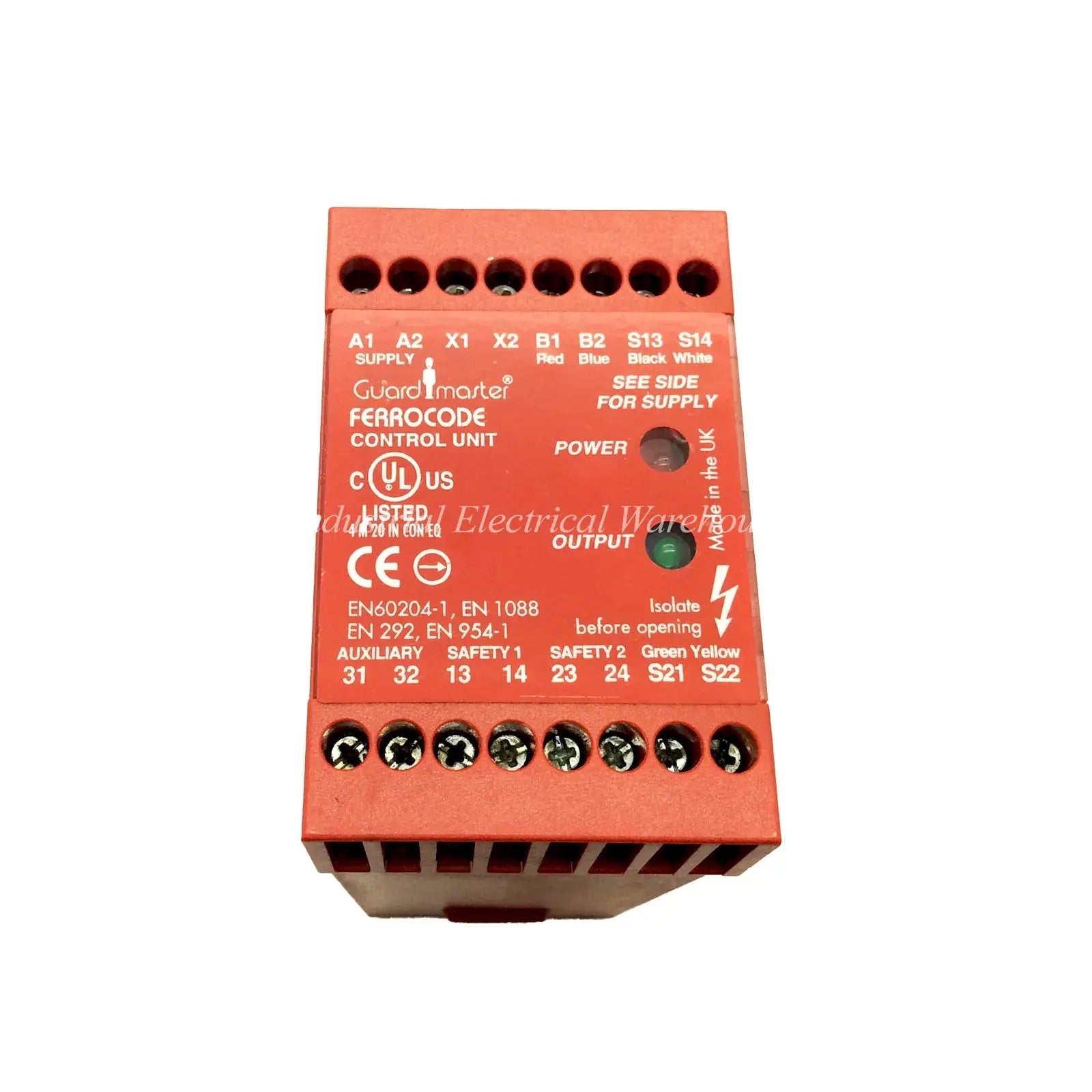

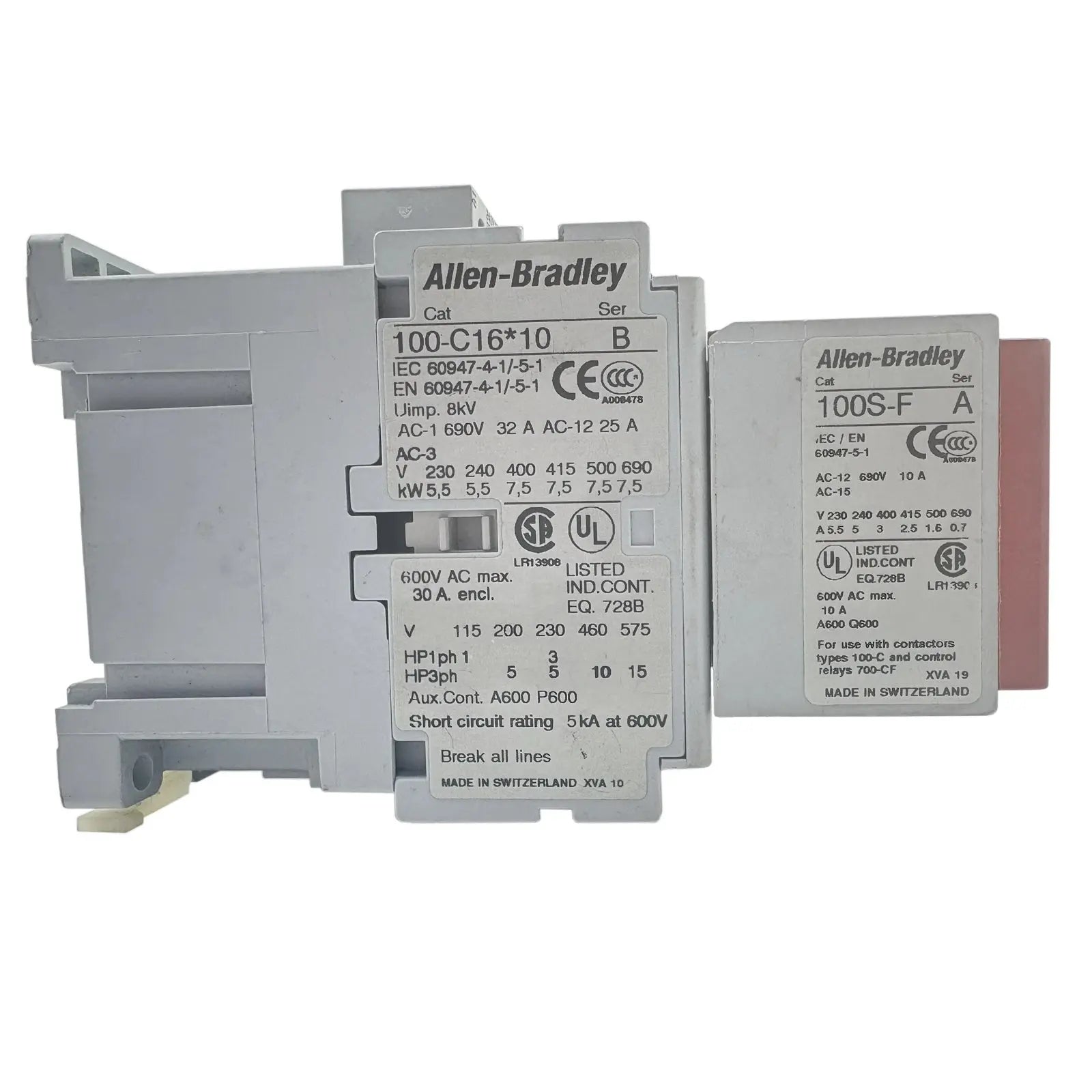

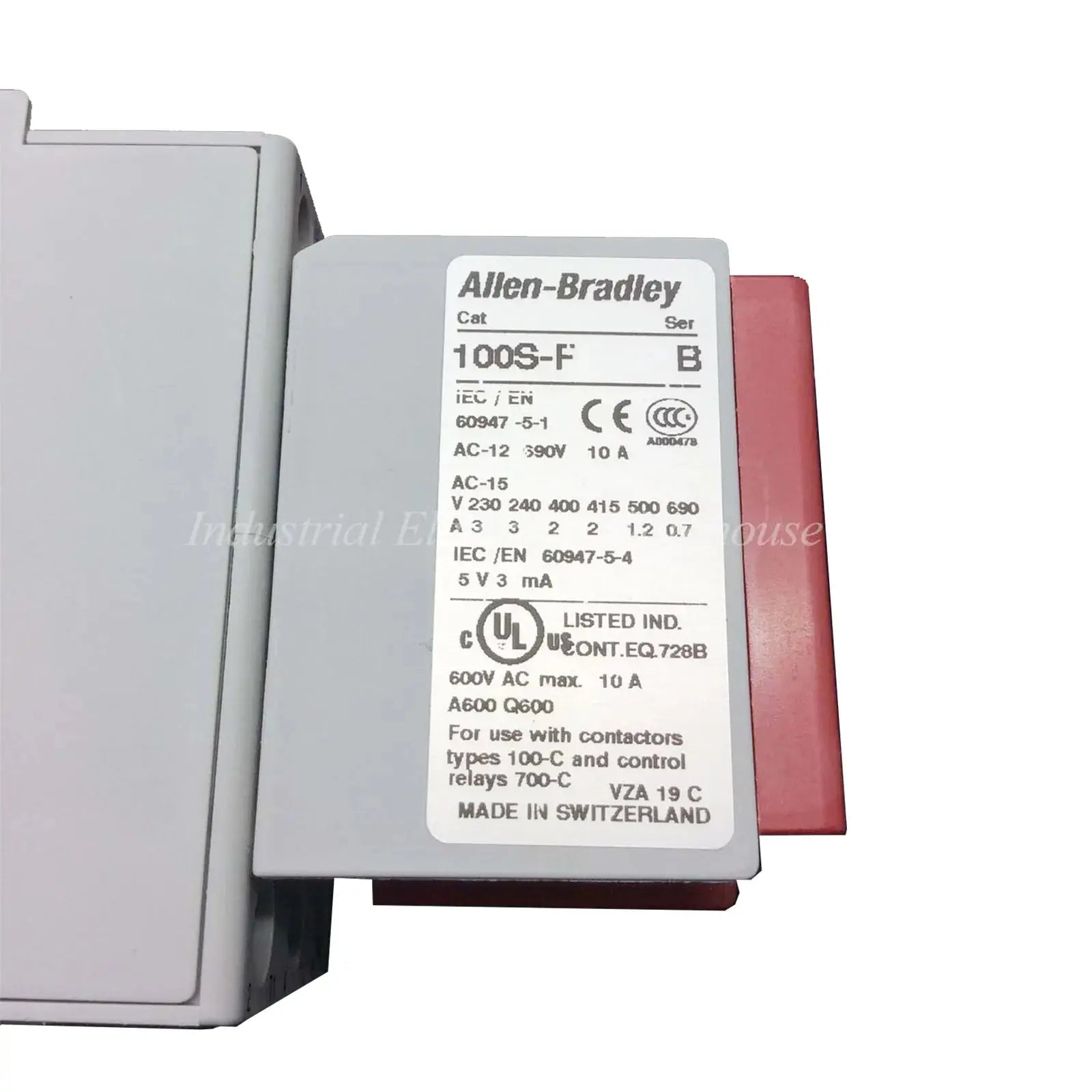

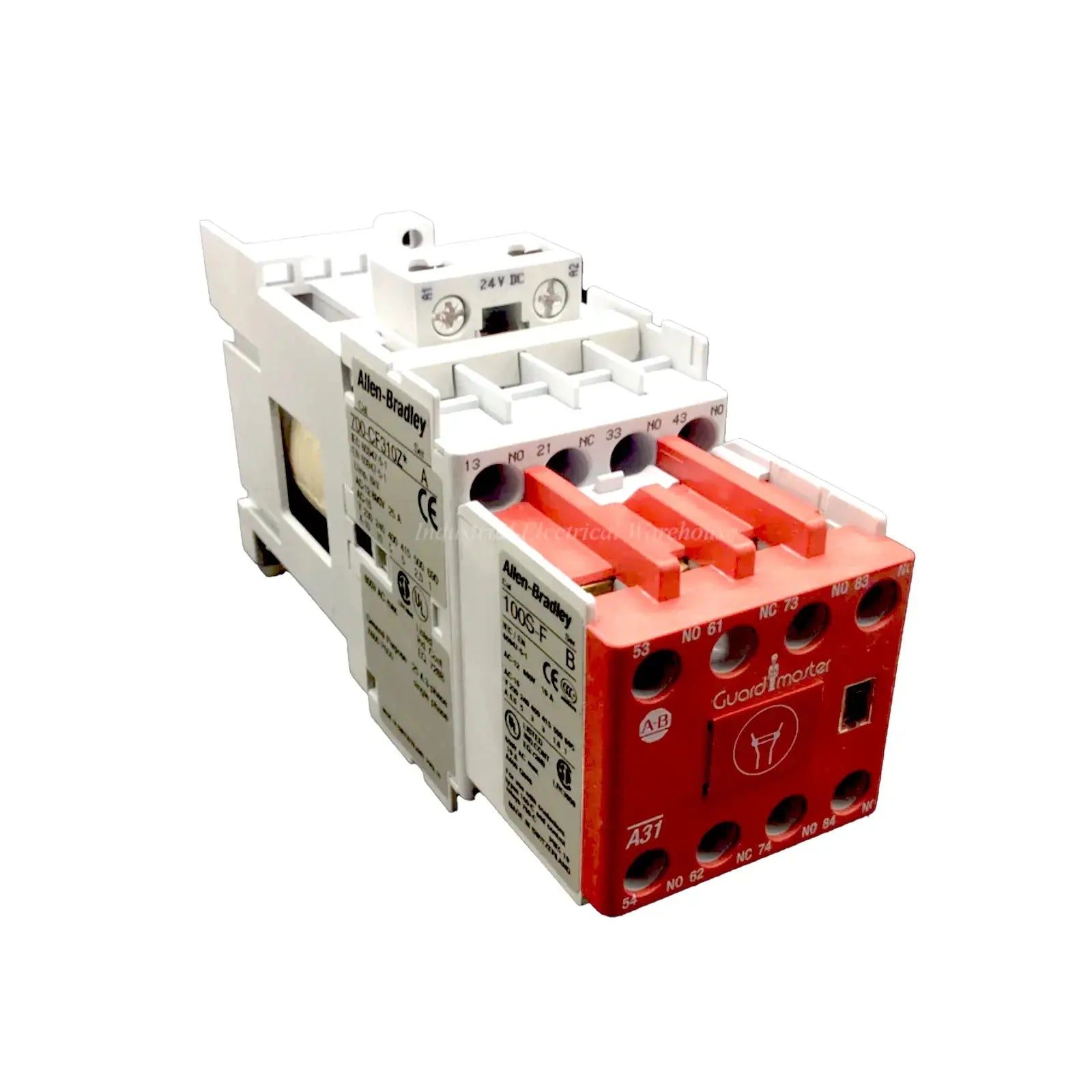

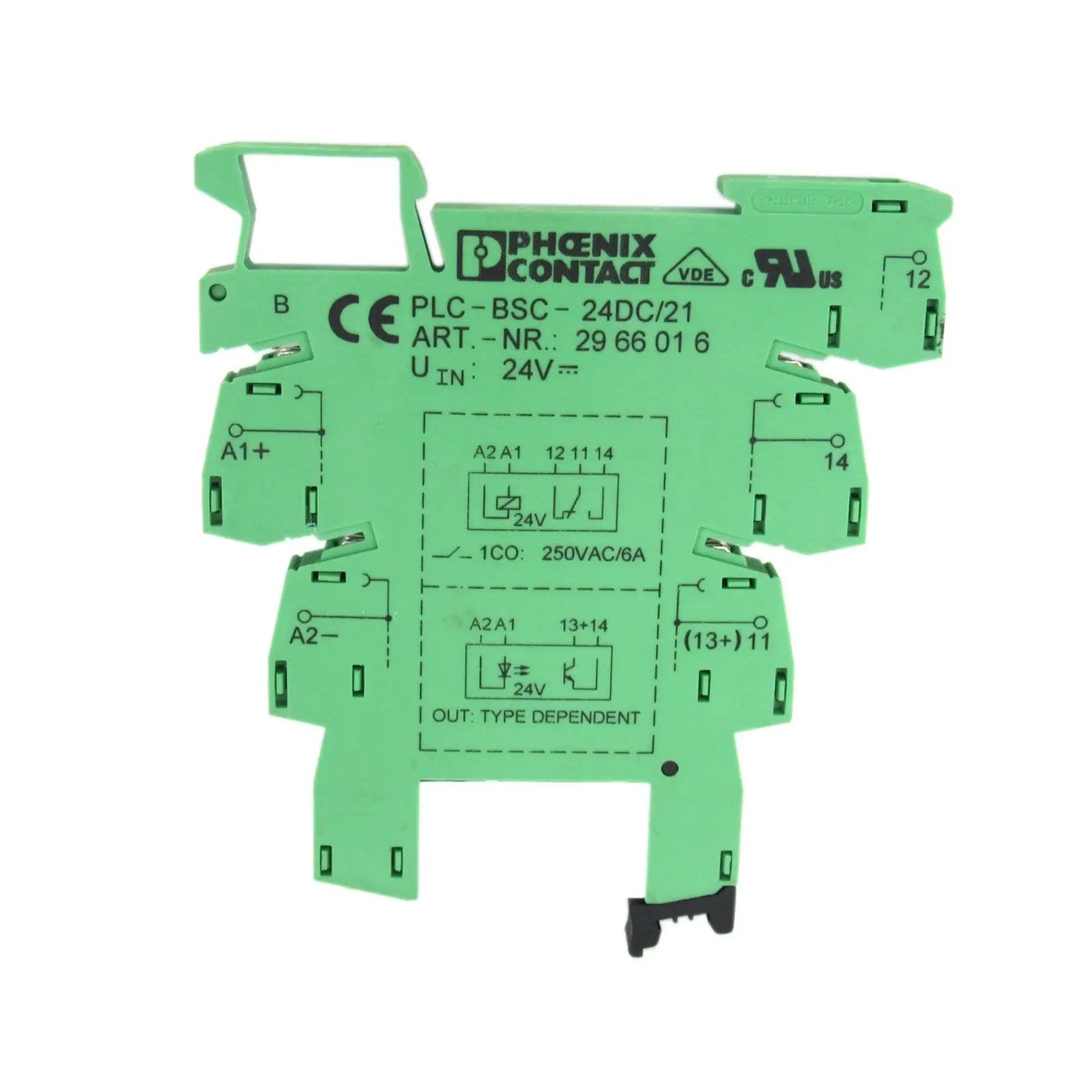

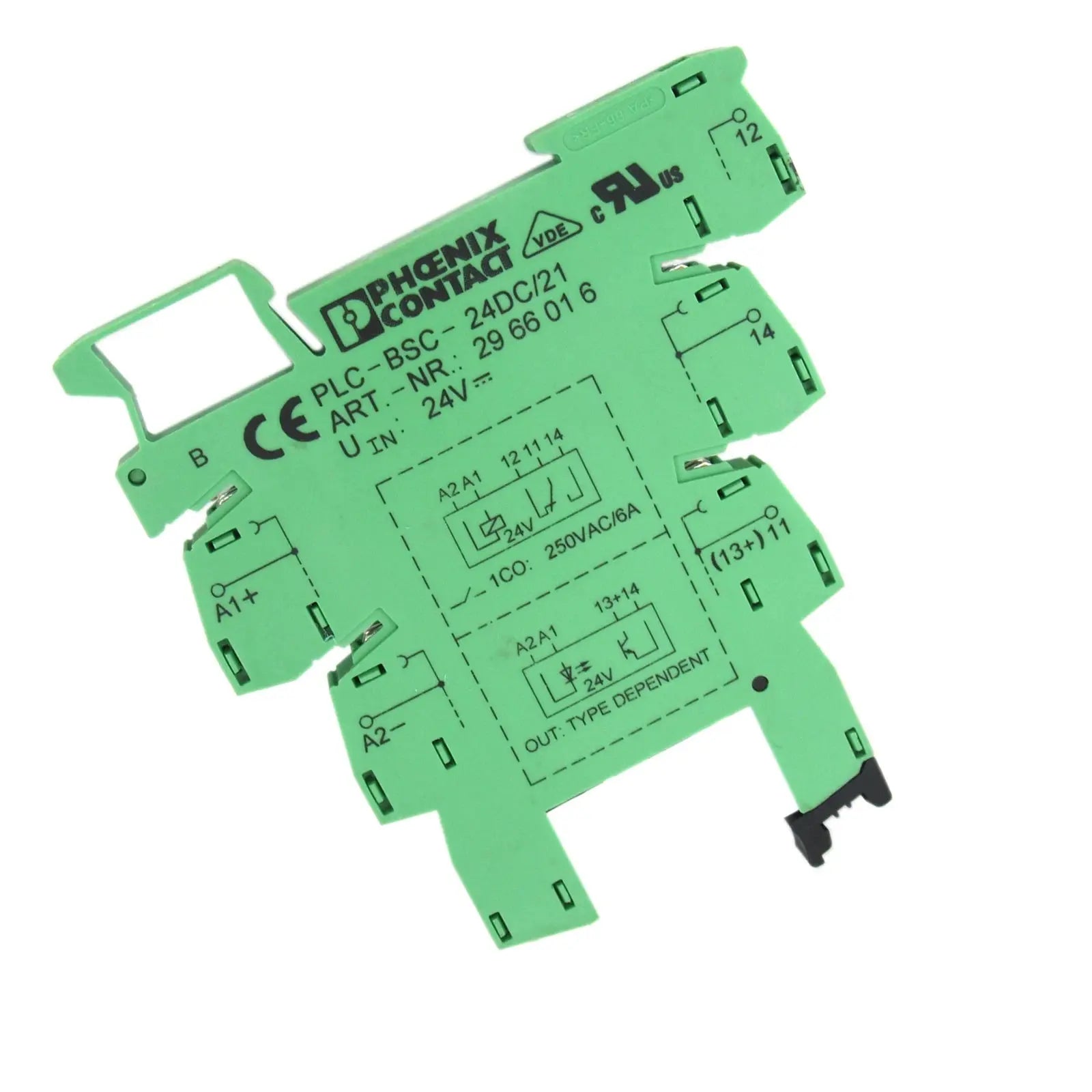

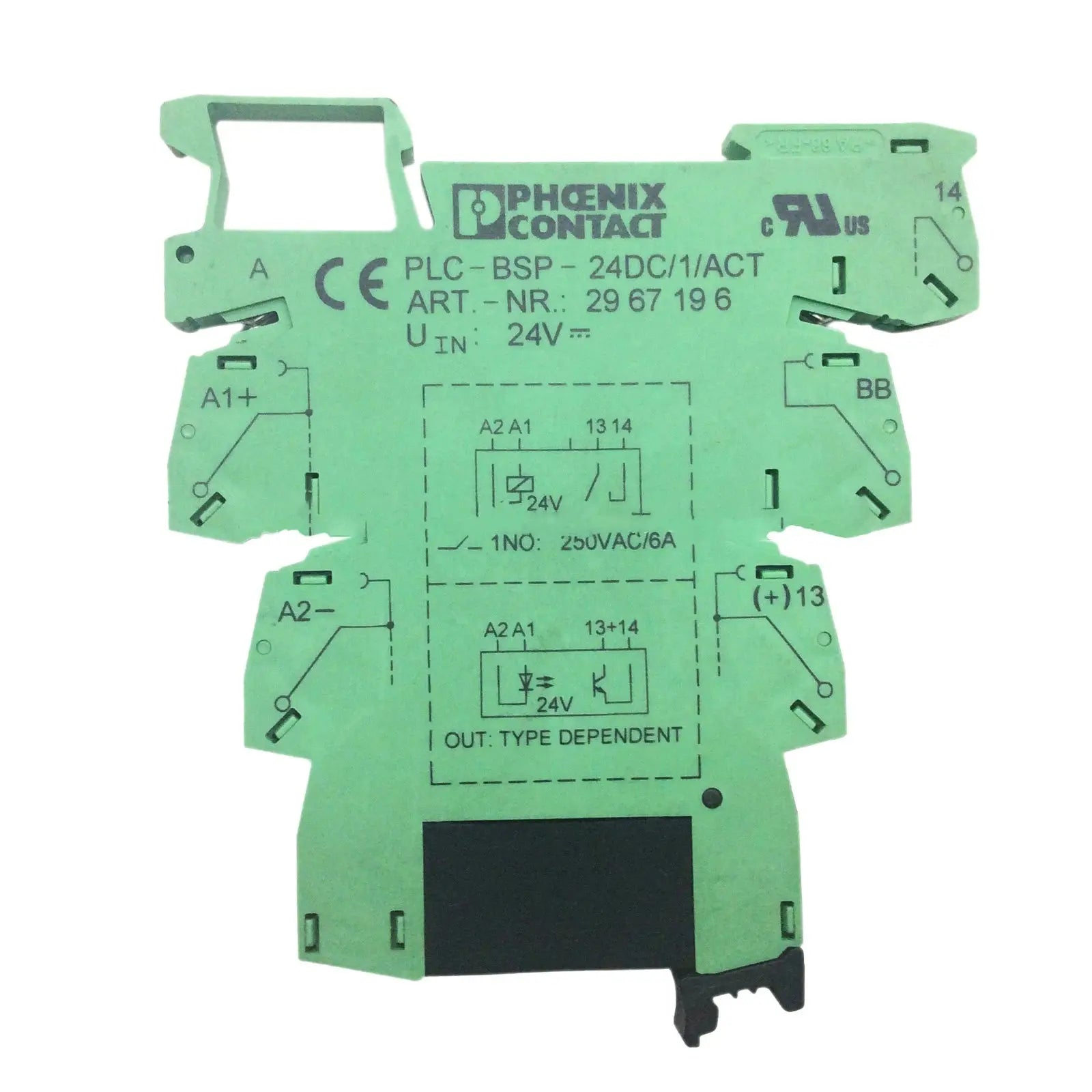

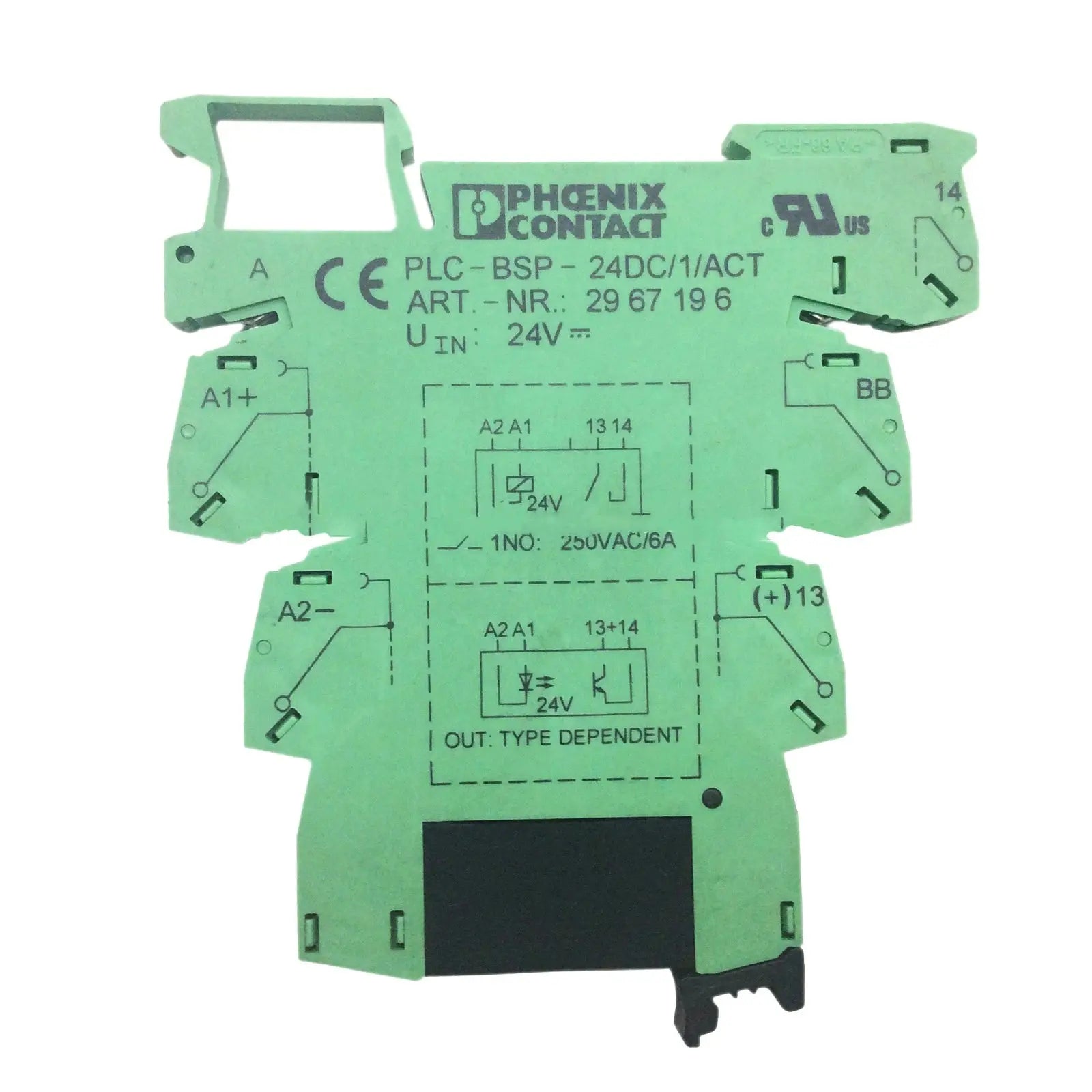

Safety and control relays are vital components in electrical systems, designed to monitor, control, and protect equipment and personnel. They are used in safety circuits, automation systems, and industrial machinery to ensure that operations run smoothly and hazards are minimized. Our range includes relays suitable for diverse applications, from machine safety to process control.

How Do Our Safety & Control Relays Ensure Protection and Reliability?

Each safety and control relay in our collection is engineered for precision, durability, and compliance with strict safety standards. They deliver reliable monitoring, fast response times, and consistent performance to safeguard equipment and operators in various environments.

Need Bulk Orders or Expert Recommendations on Safety & Control Relays?

Our team is ready to help you choose the right relay for your needs, offering technical advice, custom quotes, and product solutions tailored to your project.

📩 Contact Us or chat with us live for instant assistance!

Explore Our Monthly Madness Deals Collection!

Don't miss out on huge savings across our store! Check out the best deals in:

Explore these categories now and grab the best deals before they're gone!

- All Products in Our Range – Top-quality products handpicked for you.

- Best Sellers – Customer favourites and high-demand items.

- Watts Hot Deals and Sales – Limited-time discounts on must-have products.

- Watts New – Fresh arrivals and the latest innovations.

-

All Collections – Explore everything we have to offer.

Explore these categories now and grab the best deals before they're gone!

Don't forget to Check out our Massive Markdowns While Stocks Last!

Recently viewed

Watts Current Newsletter

Stay connected with the latest industrial electrical products, exclusive deals, and expert updates.

Sign up now and never miss out