Push Buttons

70 products

Showing 1 - 48 of 70 products

High-Quality Push Buttons for Every Industrial Application

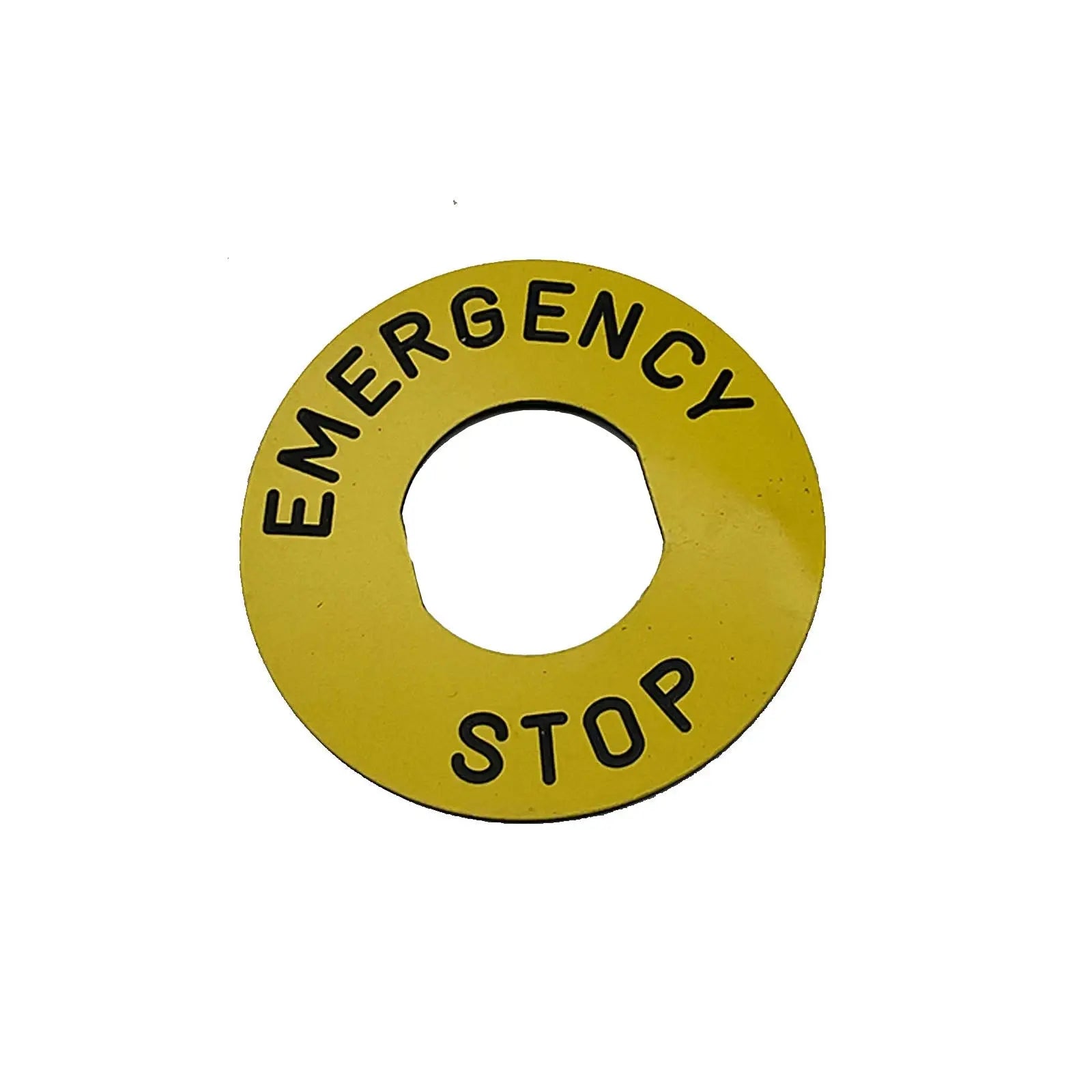

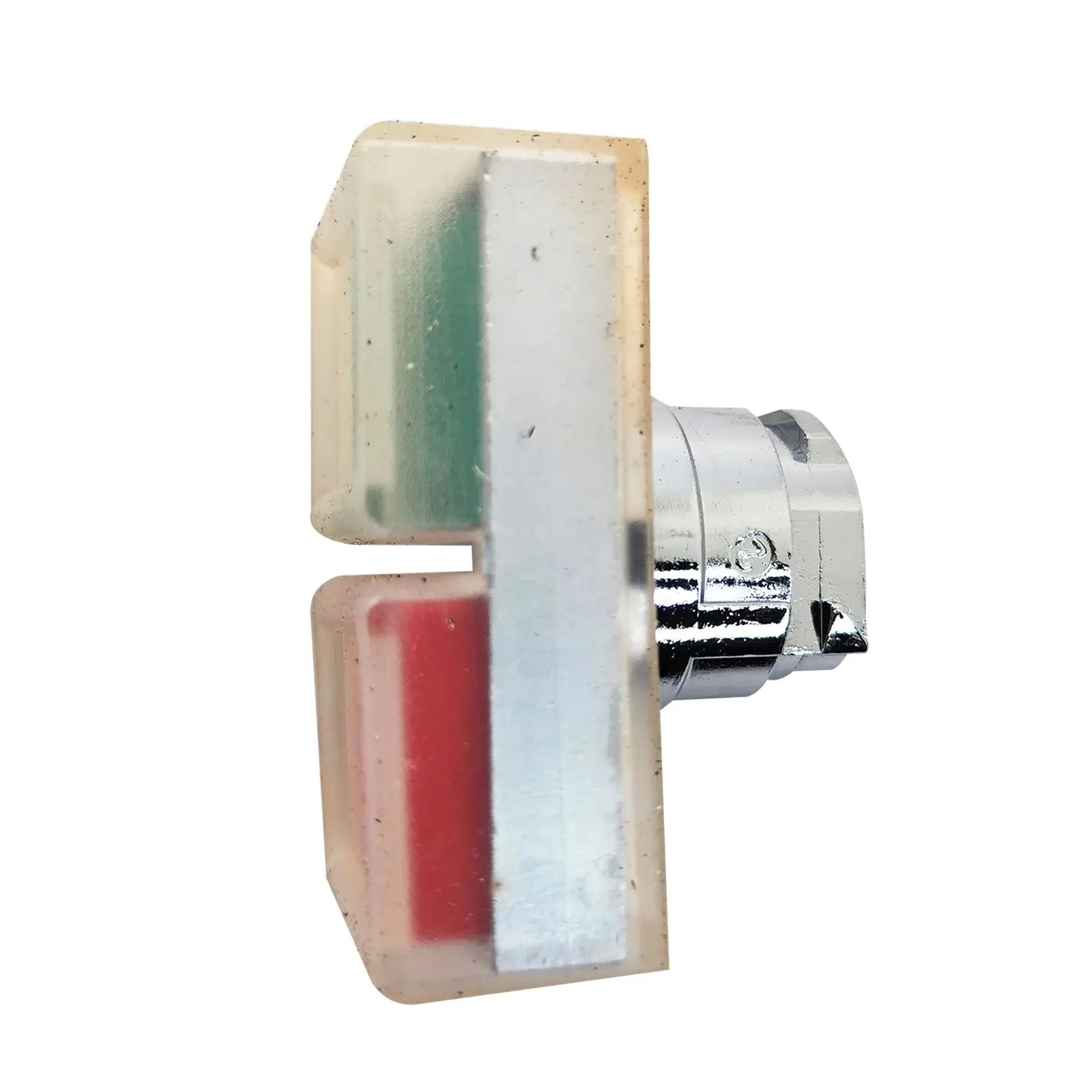

Discover our premium collection of push buttons, ideal for control panels, machinery, automation systems, and safety circuits. Built to meet industrial demands, our push buttons offer high durability, quick response, and reliable operation. Whether you're upgrading your equipment or assembling a new system, we provide a wide selection suited for various electrical and mechanical applications.

Why Choose Our Push Buttons?

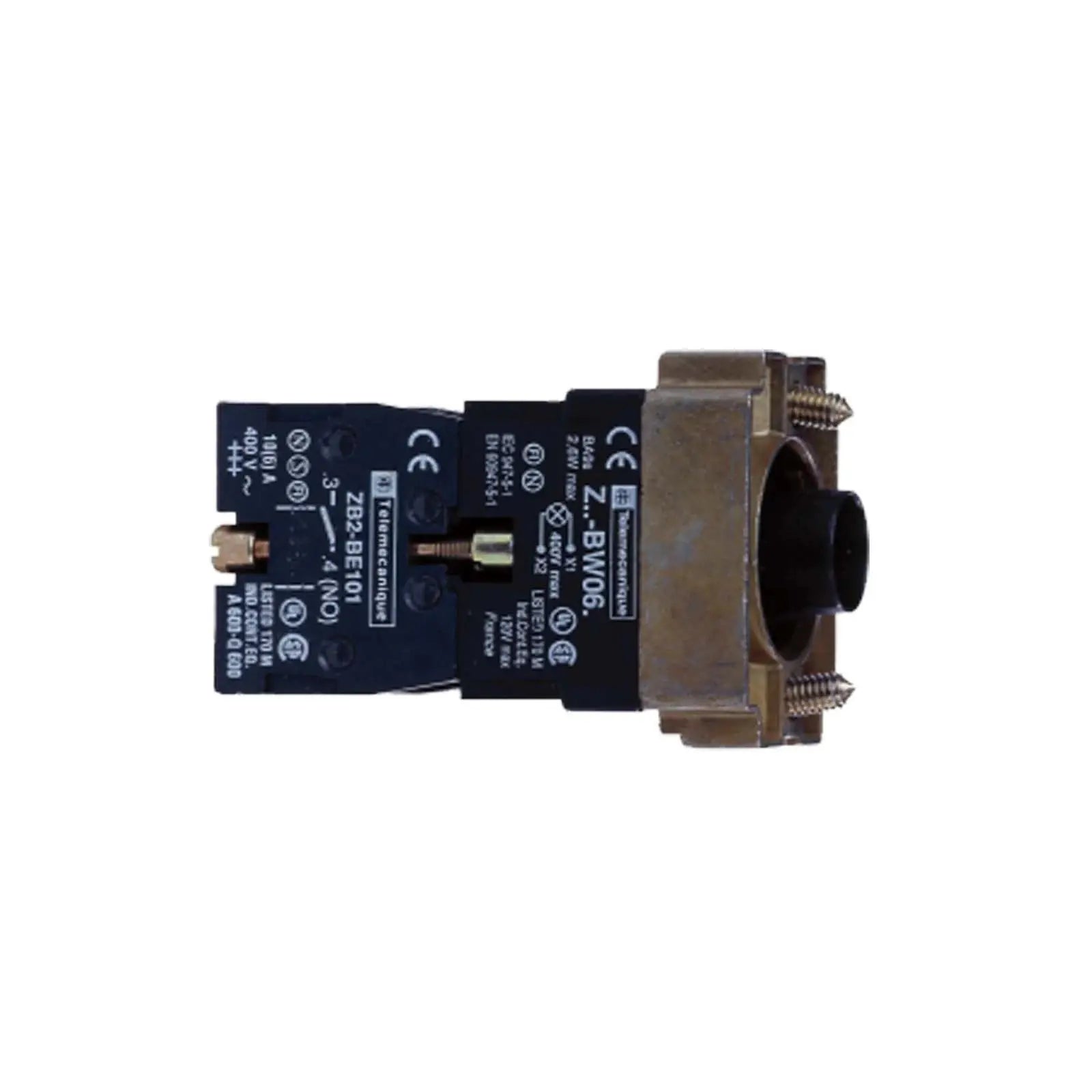

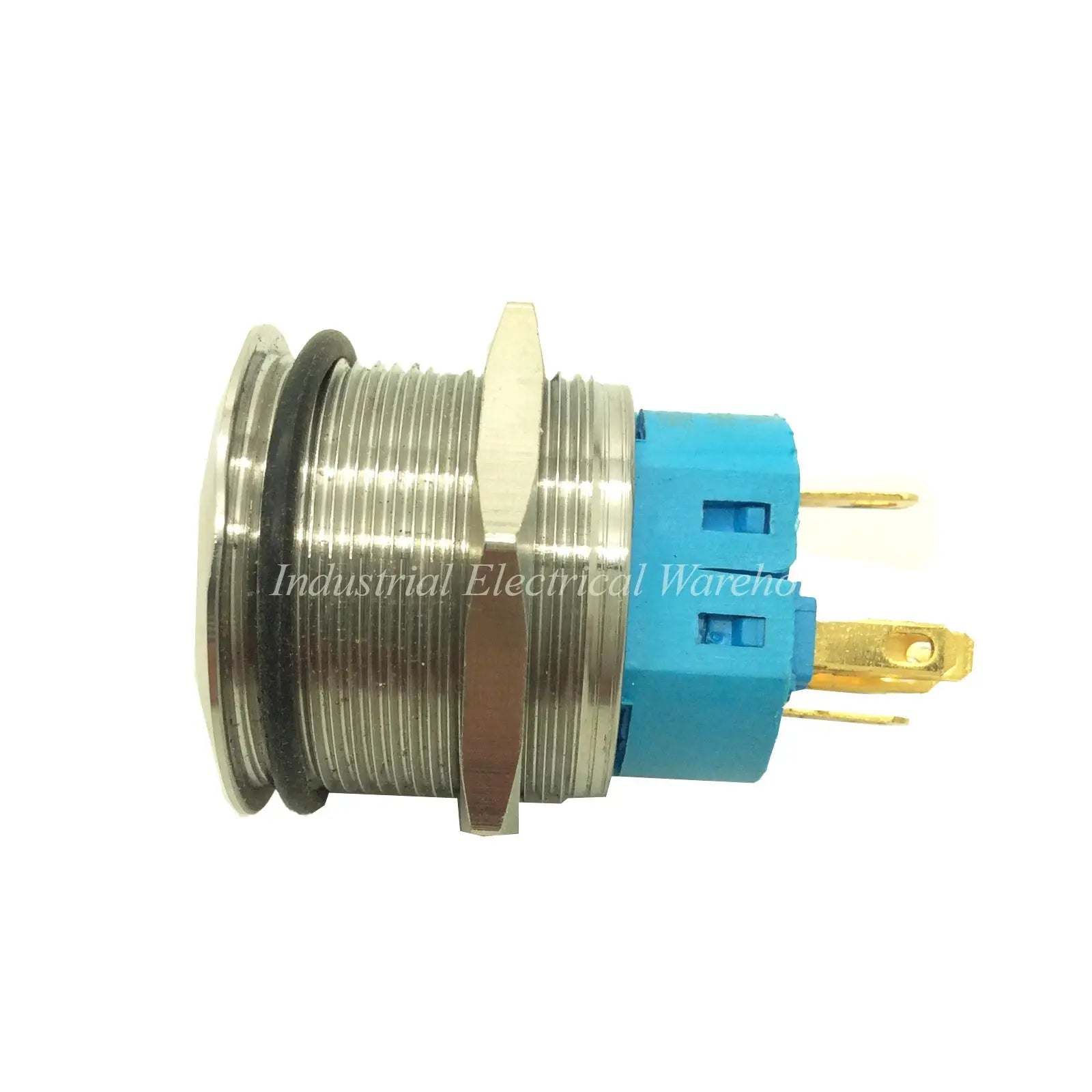

Our push buttons are manufactured from high-quality materials for long-term durability and performance. With options such as momentary, latching, illuminated, and emergency stop buttons, our collection supports a wide variety of configurations and voltages. They’re available in multiple colors, sizes, and mounting styles—ensuring compatibility with your system. Each product is tested to meet international safety and performance standards, making them ideal for use in industrial automation, control cabinets, machinery start/stop functions, and more.

How to Select and Install the Right Push Button?

Choosing the right push button depends on the voltage rating, contact type (N/O or N/C), and application environment. For installation, ensure compatibility with the panel cutout and wiring system. Most push buttons are designed for quick snap-in or screw-type mounting and easy wire connections, enabling a hassle-free setup.

Need Bulk Orders or Expert Recommendations on Push Buttons?

Looking for bulk push button orders or unsure which type suits your project? Our team offers custom quotes, expert product suggestions, and full technical support. Whether you're an engineer, technician, or supplier, we’re here to help with tailored solutions to meet your industrial requirements.

📩 Contact Us or chat with us live for instant assistance!

Explore Our Monthly Madness Deals Collection!

Don't miss out on **huge savings** across our store! Check out the best deals in:

Explore these categories now and grab the best deals before they're gone!

- All Products in Our Range – Top-quality products handpicked for you.

- Best Sellers – Customer favourites and high-demand items.

- Watts Hot Deals and Sales – Limited-time discounts on must-have products.

- Watts New – Fresh arrivals and the latest innovations.

-

All Collections – Explore everything we have to offer.

Explore these categories now and grab the best deals before they're gone!

Don't forget to Check out our Massive Markdowns While Stocks Last!

Recently viewed

Watts Current Newsletter

Stay connected with the latest industrial electrical products, exclusive deals, and expert updates.

Sign up now and never miss out