Interface

12 products

Showing 1 - 12 of 12 products

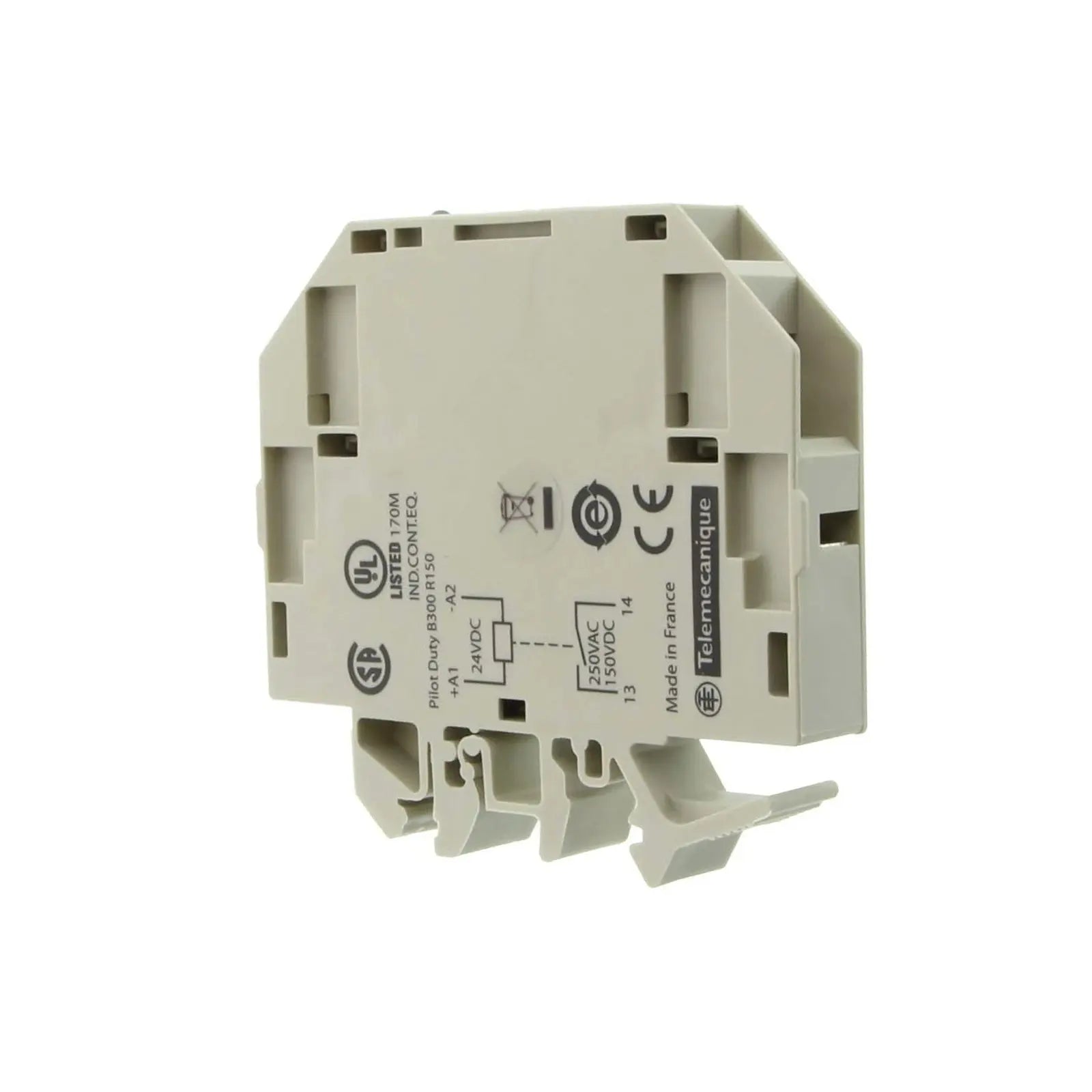

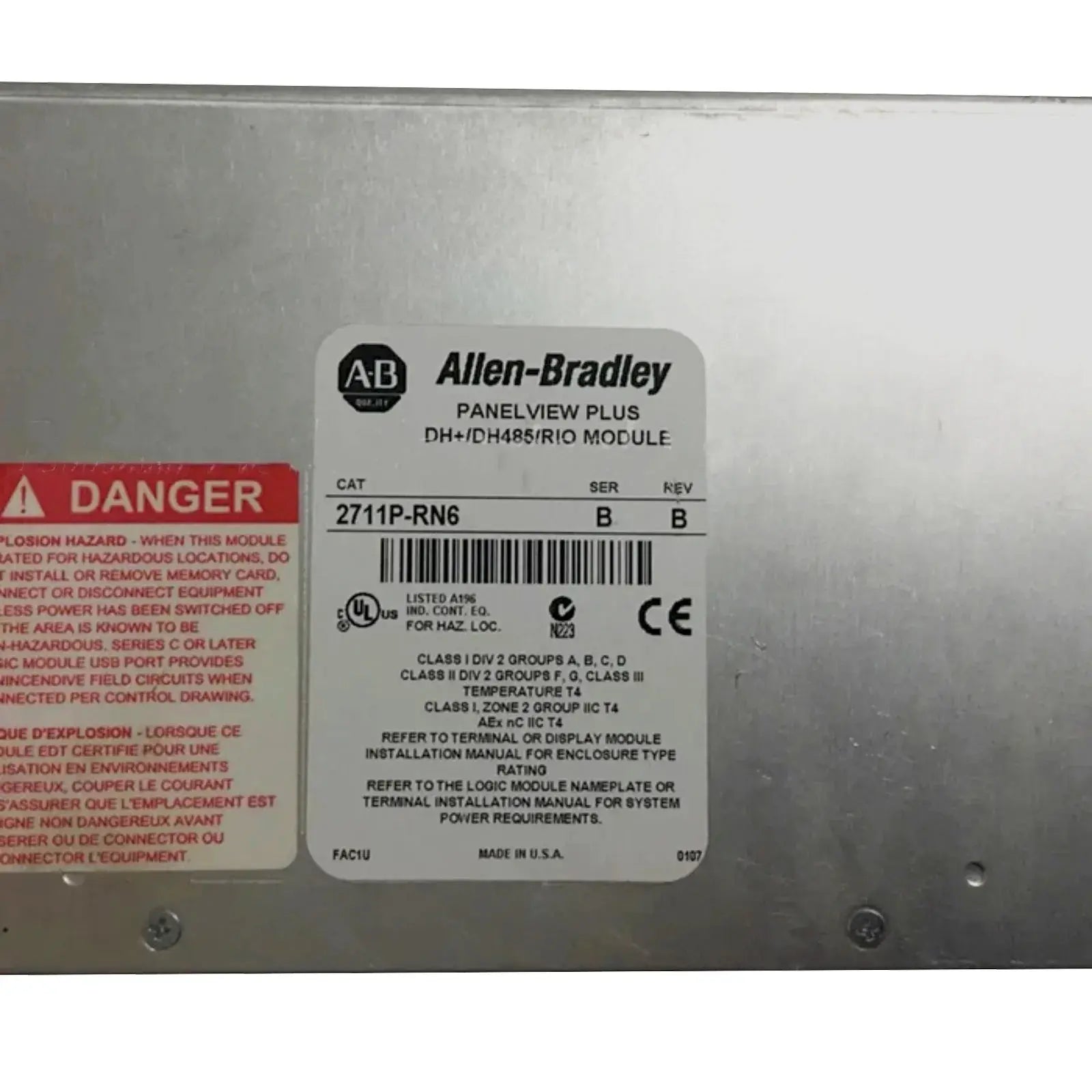

Browse our comprehensive range of interface products, designed to enhance communication and connectivity across industrial, commercial, and automation systems. Our interface solutions ensure compatibility, safety, and efficiency—making them an essential part of modern control systems.

Why Choose Our Interface Products?

Our interface components are built for performance and dependability. From signal converters to terminal blocks and relay modules, every item in our collection is engineered using high-quality materials and tested for reliability. These components help streamline data transmission, reduce wiring complexity, and improve system diagnostics. Whether you're upgrading an existing setup or building a new one, our interface solutions provide the perfect balance of flexibility and function.

How to Integrate Interface Components Effectively?

Start by identifying the type of signal or connection your system requires. Our interface modules are easy to install, with user-friendly designs that allow for secure mounting and quick wiring. Always follow manufacturer guidelines to ensure optimal compatibility and safety.

Need Bulk Orders or Expert Recommendations on Interface Products?

Whether you're sourcing for industrial automation, panel building, or factory maintenance, our team can assist with product advice, technical support, and competitive bulk pricing tailored to your project requirements.

📩 Contact Us or chat with us live for instant assistance!

Explore Our Monthly Madness Deals Collection!

Don't miss out on **huge savings** across our store! Check out the best deals in:

Explore these categories now and grab the best deals before they're gone!

- All Products in Our Range – Top-quality products handpicked for you.

- Best Sellers – Customer favourites and high-demand items.

- Watts Hot Deals and Sales – Limited-time discounts on must-have products.

- Watts New – Fresh arrivals and the latest innovations.

-

All Collections – Explore everything we have to offer.

Explore these categories now and grab the best deals before they're gone!

Don't forget to Check out our Massive Markdowns While Stocks Last!

Recently viewed

Watts Current Newsletter

Stay connected with the latest industrial electrical products, exclusive deals, and expert updates.

Sign up now and never miss out