Festo

109 produits

Affiche 97 - 109 de 109 produits

Festo : leader de l'innovation en matière d'automatisation et de solutions industrielles

Festo est un leader mondial des technologies d'automatisation, spécialisé dans les produits et solutions hautes performances pour les applications industrielles. Spécialisé dans la pneumatique, les vannes et les composants d'automatisation, Festo est à la pointe de l'innovation industrielle. Ses produits sont conçus pour allier précision, fiabilité et efficacité, garantissant des performances accrues dans divers secteurs, notamment la fabrication, l'automatisation et la robotique.

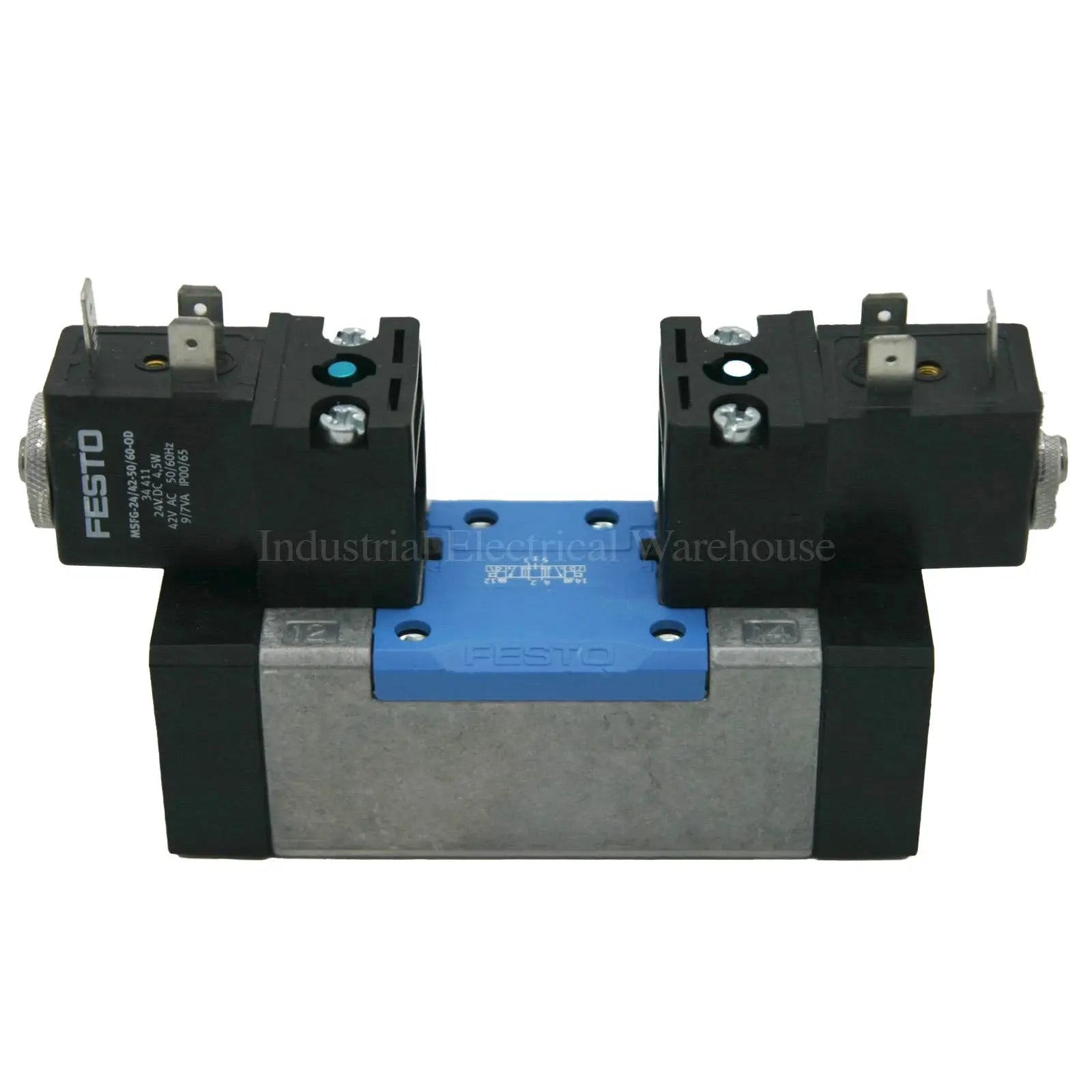

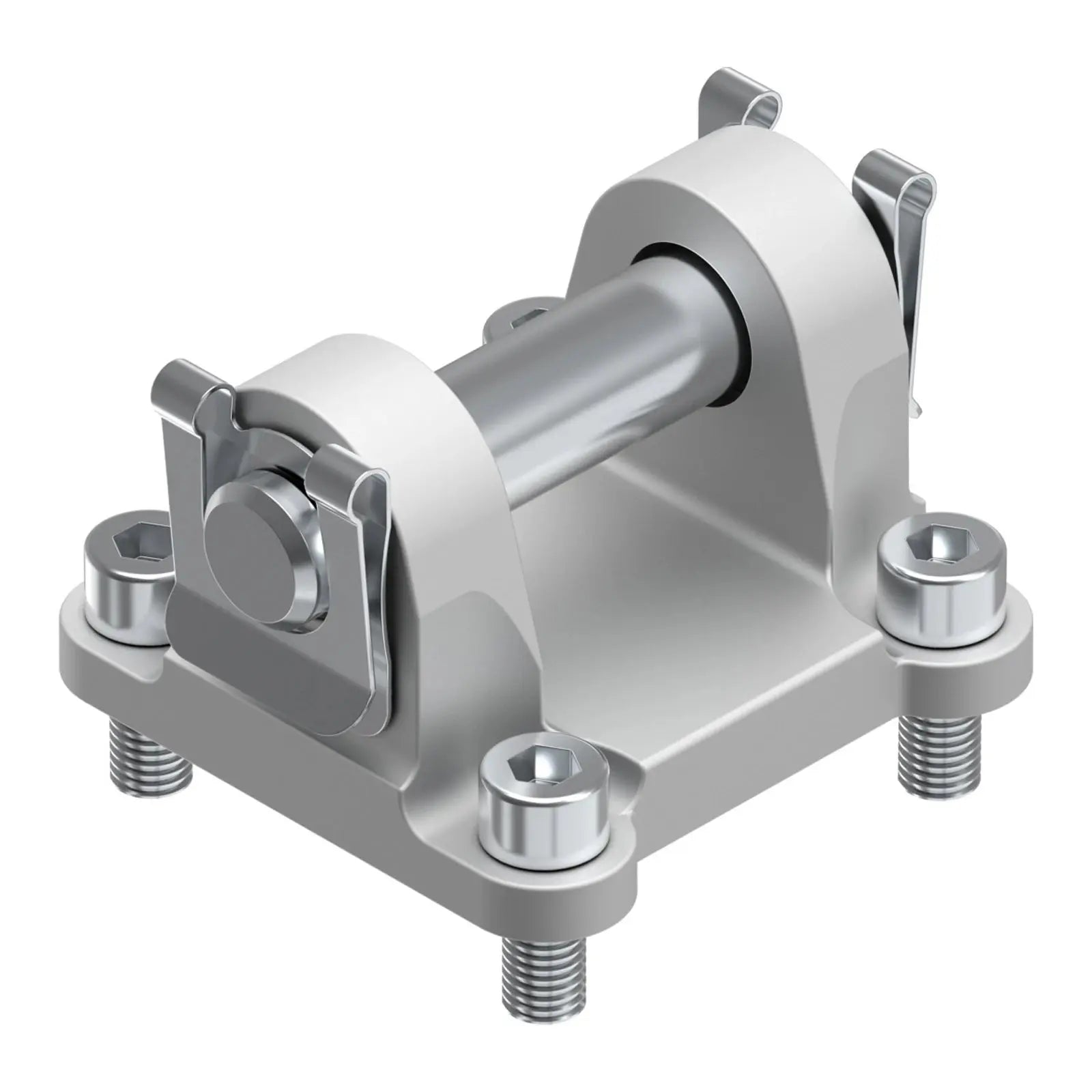

Produits et technologies Festo

Festo propose une large gamme de produits, comprenant des vannes, des automates programmables, des systèmes pneumatiques et d'autres composants d'automatisation essentiels. Leur technologie de pointe offre des solutions intelligentes qui améliorent la productivité et réduisent les temps d'arrêt. Des composants individuels aux systèmes d'automatisation complets, les solutions Festo sont conçues pour optimiser les performances, rationaliser les opérations et répondre aux besoins évolutifs des industries du monde entier.

Festo Automatisation et solutions industrielles

Les solutions d'automatisation Festo sont conçues pour s'intégrer parfaitement aux processus industriels complexes. Leurs systèmes PLC, leurs technologies de vannes et leurs systèmes pneumatiques aident les entreprises à automatiser et à optimiser leurs lignes de production, améliorant ainsi l'efficacité et réduisant l'intervention humaine. Les produits Festo sont conçus pour répondre aux normes de fiabilité et de durabilité les plus strictes, garantissant des performances constantes et durables dans des environnements exigeants.

Achetez Festo en ligne

La boutique en ligne de Festo vous permet d'accéder facilement à une grande variété de produits et composants d'automatisation. Que vous ayez besoin de vannes, d'automates programmables, de systèmes pneumatiques ou d'autres solutions d'automatisation, la plateforme e-commerce de Festo simplifie la navigation, l'achat et la livraison directe de vos produits.

Pourquoi choisir Festo ?

Festo est reconnu pour son engagement en matière d'innovation et de produits de haute qualité. Sa technologie de pointe et ses composants fiables sont reconnus par les industries du monde entier. Que vous recherchiez des systèmes pneumatiques, d'automatisation ou des vannes industrielles, Festo propose des solutions fiables conçues pour optimiser vos opérations.

Besoin de commandes en gros ou de recommandations d'experts sur Festo ?

Vous souhaitez commander des produits Festo en gros ou avez besoin d'aide pour choisir la solution industrielle idéale ? Notre équipe est là pour vous aider avec des devis personnalisés, des recommandations de produits et des conseils techniques. Que vous soyez électricien, entrepreneur ou chef d'entreprise, nous proposons des solutions sur mesure pour répondre à vos besoins.

📩 Contactez-nous ou discutez avec nous en direct pour une assistance instantanée !

Découvrez notre collection mensuelle d'offres de folie !

Profitez de réductions exceptionnelles dans notre magasin ! Découvrez les meilleures offres :

Explorez ces catégories maintenant et profitez des meilleures offres avant qu'elles ne disparaissent !

- Tous les produits de notre gamme – Des produits de qualité supérieure sélectionnés avec soin pour vous.

- Meilleures ventes – Articles préférés des clients et articles très demandés.

- Offres spéciales et soldes Watts – Remises à durée limitée sur des produits incontournables.

- Watts New – Nouveautés et dernières innovations.

-

Toutes les collections – Explorez tout ce que nous avons à offrir.

Explorez ces catégories maintenant et profitez des meilleures offres avant qu'elles ne disparaissent !

N'oubliez pas de consulter nos remises massives jusqu'à épuisement des stocks !

Vu récemment

Bulletin d'information Watts Current

Restez connecté avec les derniers produits électriques industriels, les offres exclusives et les mises à jour d'experts.

Inscrivez-vous maintenant et ne manquez rien