Interrupteurs de fin de course : contrôle et surveillance précis en milieu industriel

Dans le monde de l'automatisation industrielle, le contrôle et la surveillance de précision sont essentiels au bon fonctionnement des machines et des processus. L'interrupteur de fin de course est un composant essentiel qui joue un rôle majeur dans l'obtention de ce niveau de contrôle. Comprendre les bases des interrupteurs de fin de course est essentiel pour toute personne travaillant dans le secteur industriel.

Comprendre les bases des interrupteurs de fin de course

Définition et fonction des interrupteurs de fin de course

Un interrupteur de fin de course est un dispositif utilisé pour détecter la présence ou l'absence d'un objet, généralement par des moyens mécaniques. Il est composé d'un actionneur et d'un ensemble de contacts, qui s'activent lorsque l'actionneur entre en contact avec l'objet surveillé. La fonction principale de l'interrupteur est de fournir une indication fiable et précise de la position ou de la limite de l'objet.

Les interrupteurs de fin de course jouent un rôle crucial dans divers secteurs et applications. Par exemple, dans les usines de fabrication, ils assurent l'arrêt des machines lorsqu'une position ou une limite spécifique est atteinte. Cela permet d'éviter d'endommager les équipements et de garantir la sécurité des opérateurs. Dans les systèmes automatisés, les interrupteurs de fin de course contrôlent le mouvement des bras robotisés, garantissant ainsi un positionnement précis et évitant les collisions.

Types d'interrupteurs de fin de course

Les interrupteurs de fin de course sont disponibles en différents types pour répondre aux exigences des différentes applications. Les plus courants sont :

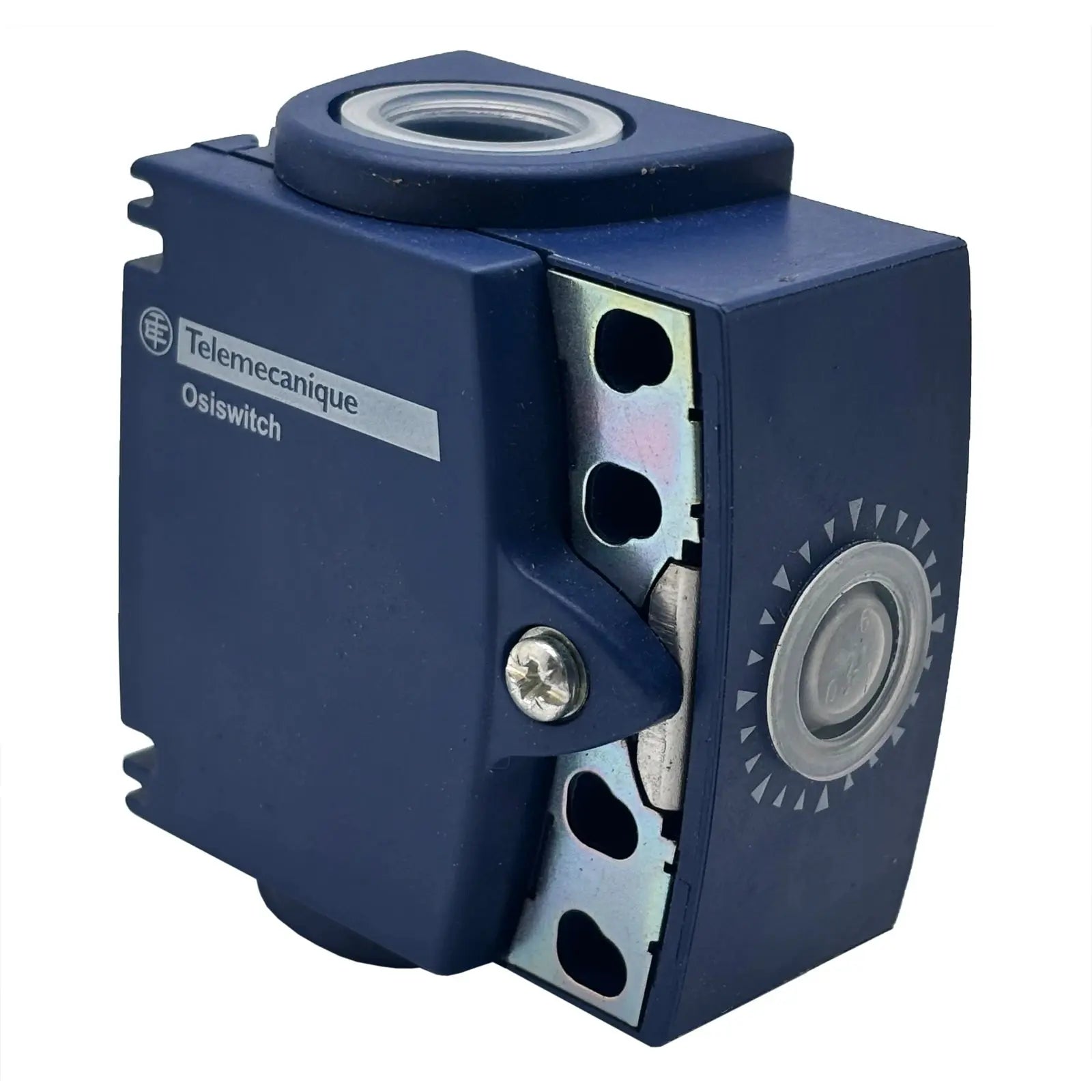

Interrupteurs de fin de course standard : Ces interrupteurs sont dotés d'un actionneur mécanique et conviennent aux applications générales. Réputés pour leur durabilité et leur fiabilité, ils constituent un choix populaire dans des secteurs tels que l'automobile, l'emballage et la manutention.

Interrupteurs de proximité : Au lieu d'un actionneur mécanique, ces interrupteurs utilisent des technologies électroniques ou magnétiques pour détecter la présence d'un objet. Ils sont souvent utilisés dans les applications où le contact physique avec l'objet surveillé est déconseillé, comme dans les salles blanches ou les environnements dangereux.

Interrupteurs de fin de course de sécurité : Ces interrupteurs sont conçus pour assurer la sécurité du personnel et des équipements en surveillant les paramètres critiques et en déclenchant les actions appropriées en cas d'urgence. Ils sont dotés de fonctionnalités supplémentaires telles que des contacts redondants, des boîtiers inviolables et des fonctions d'autosurveillance.

Chaque type d'interrupteur de fin de course présente ses propres avantages et est adapté à des applications spécifiques. Choisir le bon type d'interrupteur de fin de course est crucial pour garantir des performances et une fiabilité optimales dans une application donnée.

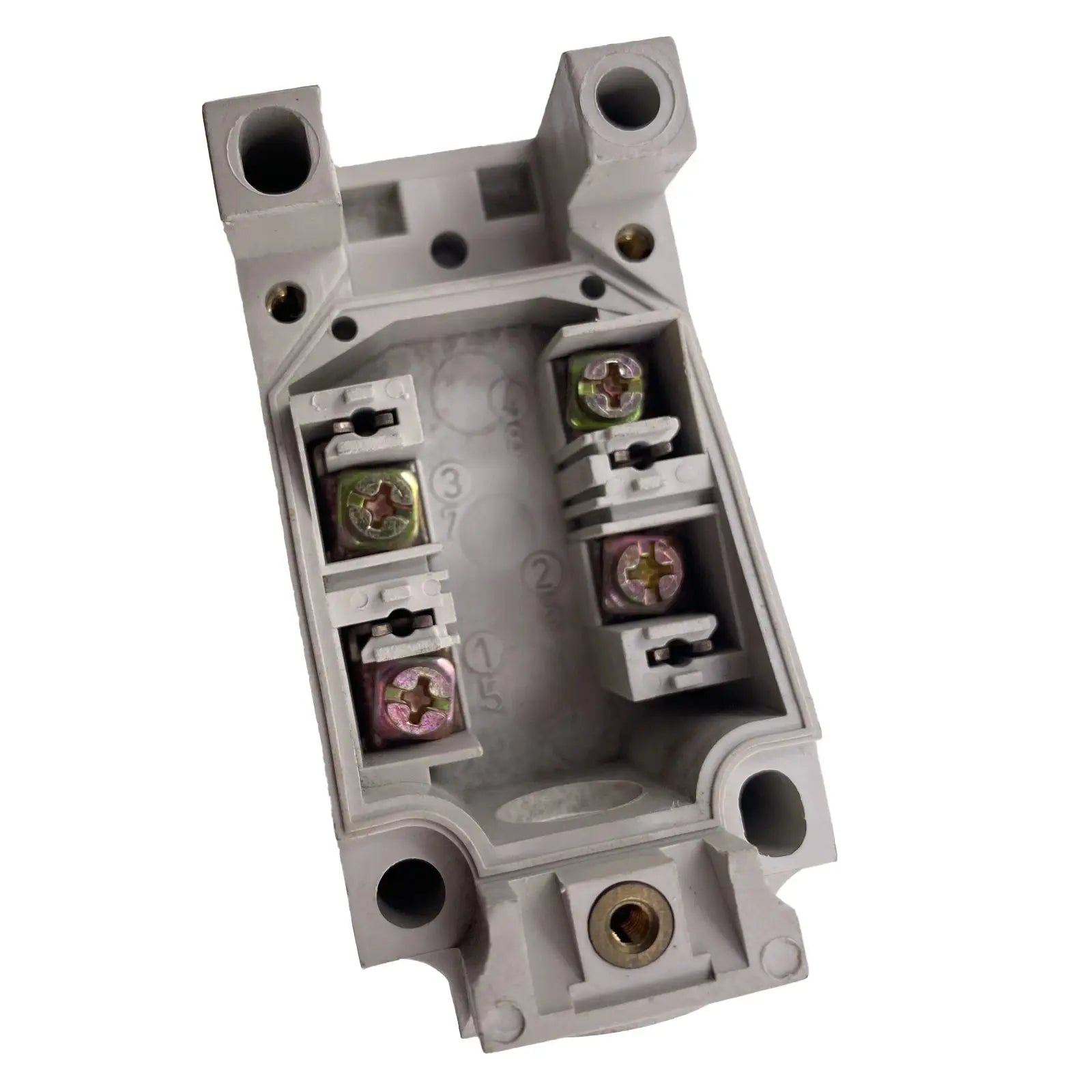

Composants clés des interrupteurs de fin de course

Comprendre les composants clés des interrupteurs de fin de course est essentiel pour comprendre leur fonctionnement. Les principaux composants sont :

Actionneur : partie de l'interrupteur de fin de course qui entre en contact avec l'objet surveillé. Il peut s'agir d'un levier, d'un galet, d'un poussoir ou de tout autre mécanisme permettant à l'interrupteur de détecter la position de l'objet.

Contacts : Ce sont les interrupteurs électriques qui s'ouvrent ou se ferment lorsque l'actionneur est activé. Les contacts sont chargés d'envoyer des signaux au système de contrôle ou à l'alimentation électrique, indiquant la position de l'objet.

Boîtier : Le boîtier de protection abrite les composants internes de l'interrupteur de fin de course. Il est conçu pour assurer une protection mécanique et environnementale, garantissant ainsi la longévité et les performances de l'interrupteur dans diverses conditions de fonctionnement.

Bornes de connexion : Bornes permettant de connecter l'interrupteur de fin de course au système de commande ou à l'alimentation. Ces bornes facilitent l'installation et le câblage, garantissant une connexion sûre et fiable.

Chaque composant joue un rôle crucial dans le fonctionnement global de l'interrupteur de fin de course. L'actionneur détecte la position de l'objet, les contacts fournissent des signaux électriques, le boîtier protège les composants internes et les bornes de connexion facilitent l'intégration au système.

En comprenant les principes fondamentaux des interrupteurs de fin de course, notamment leur définition, leur fonction, leurs types et leurs composants clés, vous pourrez prendre des décisions éclairées lors du choix et de l'utilisation de ces dispositifs dans vos applications. Qu'il s'agisse de garantir la sécurité, d'améliorer l'efficacité ou d'obtenir un contrôle précis, les interrupteurs de fin de course sont un outil essentiel dans le monde de l'automatisation et du contrôle.

Le rôle des interrupteurs de fin de course dans les environnements industriels

Importance d'un contrôle et d'une surveillance précis

Un contrôle et une surveillance précis sont essentiels en milieu industriel pour garantir un fonctionnement efficace et fiable. Les interrupteurs de fin de course, capables de détecter précisément la position et les limites, jouent un rôle fondamental dans la réalisation de cet objectif. Ils permettent aux machines et aux processus d'exécuter leurs tâches avec précision, améliorant ainsi la productivité et réduisant les temps d'arrêt.

Applications des interrupteurs de fin de course dans différentes industries

Les interrupteurs de fin de course trouvent des applications dans de nombreux secteurs d'activité grâce à leur polyvalence et leur fiabilité. Parmi les applications courantes, on peut citer :

Fabrication : Les interrupteurs de fin de course sont utilisés pour détecter la présence ou l'absence de composants dans les chaînes de montage et pour contrôler les mouvements robotiques.

Automobile : Ces commutateurs sont utilisés dans les usines de fabrication automobile pour le contrôle de la qualité et la détection du positionnement correct des pièces automobiles.

Manutention : les interrupteurs de fin de course sont essentiels dans les systèmes de convoyeurs, garantissant un alignement correct et évitant les bourrages ou les surcharges.

Pétrole et gaz : dans les environnements dangereux, les interrupteurs de fin de course assurent la sécurité en surveillant les positions des vannes et en garantissant un bon fonctionnement.

Mesures de sécurité activées par les interrupteurs de fin de course

La sécurité industrielle est primordiale, et les interrupteurs de fin de course contribuent grandement à la sécurité de l'environnement de travail. Ils permettent de détecter la présence ou l'absence de dispositifs de protection, de boutons d'arrêt d'urgence et d'autres composants de sécurité essentiels. En cas d'écart par rapport à la position normale, les interrupteurs de fin de course peuvent déclencher des arrêts immédiats ou activer des signaux d'avertissement pour prévenir les accidents ou les blessures.

De plus, les interrupteurs de fin de course sont essentiels non seulement à la sécurité, mais aussi à l'optimisation des processus. Par exemple, dans l'industrie manufacturière, ils jouent un rôle crucial pour garantir l'alignement précis des composants sur les chaînes de montage. En détectant précisément la présence ou l'absence de ces composants, ils permettent d'automatiser les processus de contrôle qualité, améliorant ainsi la régularité des produits et réduisant les déchets.

Dans l'industrie automobile, les interrupteurs de fin de course servent non seulement au contrôle qualité, mais aussi à améliorer l'efficacité globale des lignes de production. En détectant le positionnement correct des pièces automobiles, ils permettent d'automatiser des processus tels que le soudage et la peinture, garantissant ainsi que chaque composant est à sa place. Ce niveau de précision et d'automatisation réduit les risques d'erreur et améliore la rapidité et la précision du processus de fabrication.

La technologie derrière les interrupteurs de fin de course

Comment fonctionnent les interrupteurs de fin de course

Les interrupteurs de fin de course fonctionnent selon un principe simple mais efficace. Lorsque l'actionneur entre en contact avec l'objet surveillé, il applique une force sur les composants internes de l'interrupteur. Cette force provoque l'ouverture ou la fermeture des contacts internes, selon la conception. Ces contacts sont connectés à un système de commande ou à une alimentation électrique, ce qui leur permet d'envoyer des signaux sur la position ou la limite de l'objet.

Progrès technologiques dans la conception des interrupteurs de fin de course

Au fil des ans, la technologie des interrupteurs de fin de course a évolué pour répondre aux exigences des applications industrielles modernes. Les avancées technologiques ont permis le développement de :

Interrupteurs de fin de course miniatures : De plus petite taille, ces interrupteurs offrent le même niveau de précision et de fiabilité que leurs homologues plus grands, mais conviennent aux applications avec des contraintes d'espace.

Interrupteurs de fin de course sans fil : éliminant le besoin de câblage physique, ces interrupteurs offrent flexibilité et facilité d'installation dans des endroits éloignés ou difficiles d'accès.

Interrupteurs de fin de course intelligents : équipés de capteurs avancés et de capacités de communication, ces interrupteurs peuvent fournir des données en temps réel et s'intégrer de manière transparente dans les systèmes de contrôle industriel.

Les interrupteurs de fin de course miniatures sont de plus en plus populaires dans les secteurs où l'espace est un facteur clé. Leur format compact permet une intégration aisée dans les espaces restreints sans compromettre la précision ni la fiabilité. Ces interrupteurs sont conçus avec précision et résistent aux rigueurs des environnements industriels exigeants. Grâce à leur faible encombrement, ils constituent une solution économique pour les applications où des interrupteurs plus grands seraient peu pratiques.

Les interrupteurs de fin de course sans fil ont révolutionné la conception et la mise en œuvre des systèmes d'automatisation industrielle. En éliminant le câblage physique, ces interrupteurs offrent une plus grande flexibilité d'installation et réduisent les coûts de maintenance. Ils peuvent être facilement déployés dans des endroits éloignés ou difficiles d'accès, permettant une surveillance et un contrôle efficaces des équipements. Grâce aux progrès de la technologie sans fil, ces interrupteurs offrent désormais une communication fiable et sécurisée, garantissant une intégration transparente aux systèmes existants.

Les interrupteurs de fin de course intelligents ont révolutionné le secteur de l'automatisation industrielle. Dotés de capteurs et de capacités de communication avancés, ces interrupteurs peuvent fournir des données en temps réel sur divers paramètres, tels que la position, la température et les vibrations. Ces données peuvent être utilisées pour la maintenance prédictive, l'optimisation des processus de production et l'amélioration de l'efficacité globale du système. Grâce à leur intégration aux systèmes de contrôle industriel, les interrupteurs de fin de course intelligents permettent une automatisation et une prise de décision avancées, générant ainsi une productivité accrue et des économies de coûts.

Tendances futures de la technologie des interrupteurs de fin de course

Avec les progrès technologiques, l'avenir des interrupteurs de fin de course s'annonce prometteur. Voici quelques tendances potentielles en la matière :

Intégration IoT : Les interrupteurs de fin de course pourraient intégrer l'écosystème de l'Internet des objets (IoT), permettant un contrôle et une surveillance plus intelligents et automatisés. En connectant les interrupteurs de fin de course à un réseau, les données peuvent être collectées et analysées en temps réel, permettant une maintenance proactive et une optimisation de l'efficacité opérationnelle.

Durabilité accrue : Les fabricants s'efforcent constamment d'améliorer la durabilité et la fiabilité des interrupteurs de fin de course, garantissant ainsi leur résistance aux environnements industriels difficiles. Cela inclut des avancées dans les matériaux, les techniques d'étanchéité et les revêtements de protection, rendant les interrupteurs de fin de course plus résistants à la poussière, à l'humidité et aux températures extrêmes.

Capacités de détection accrues : Les futurs interrupteurs de fin de course pourraient bénéficier de capacités de détection améliorées, leur permettant de détecter simultanément plusieurs paramètres et de fournir des informations plus détaillées. Cela pourrait inclure la mesure de la pression, du débit ou même de la composition chimique, élargissant ainsi le champ d'application des interrupteurs de fin de course.

Avec ces avancées potentielles à l'horizon, les interrupteurs de fin de course sont appelés à jouer un rôle encore plus crucial dans l'automatisation industrielle. Leur fiabilité, leur polyvalence et leur capacité à fournir des informations cruciales sur la position et les limites des objets les rendent indispensables dans divers secteurs, de la fabrication à la robotique, en passant par l'automobile et l'aérospatiale. À mesure que la technologie évolue, les interrupteurs de fin de course continueront de s'adapter et d'innover, permettant des processus industriels plus sûrs, plus efficaces et plus intelligents.

Choisir le bon interrupteur de fin de course pour vos besoins

Facteurs à prendre en compte lors du choix d'un interrupteur de fin de course

Le choix du bon interrupteur de fin de course pour votre application spécifique nécessite un examen attentif de divers facteurs tels que :

Conditions environnementales : évaluez la température, l’humidité et la présence de poussière ou de produits chimiques pour sélectionner un commutateur capable de résister à ces conditions.

Force d'actionnement : Déterminez la force nécessaire pour activer l'interrupteur de fin de course et assurez-vous de la compatibilité avec l'objet surveillé.

Valeurs nominales électriques : Vérifiez les valeurs nominales de tension et de courant du commutateur pour vous assurer qu'elles correspondent aux exigences de votre système de contrôle.

Conception mécanique : Tenez compte des options de montage, des matériaux du boîtier et d’autres aspects mécaniques pour garantir une intégration facile dans vos machines ou équipements.

Maintenance et dépannage des interrupteurs de fin de course

Un entretien et un dépannage réguliers sont essentiels pour garantir le fonctionnement optimal des interrupteurs de fin de course. Voici quelques bonnes pratiques :

Inspection périodique : inspectez régulièrement l'interrupteur pour détecter tout dommage physique, toute connexion desserrée ou tout signe d'usure.

Nettoyage : Gardez l’interrupteur propre et exempt de débris ou de contaminants susceptibles d’affecter son fonctionnement.

Étalonnage : si nécessaire, étalonnez le commutateur pour maintenir sa précision et sa fiabilité.

Tests : effectuez des tests périodiques pour vérifier la fonctionnalité du commutateur et effectuez les ajustements nécessaires.

Meilleures pratiques pour l'installation d'interrupteurs de fin de course

L'installation peut avoir un impact significatif sur les performances et la longévité des interrupteurs de fin de course. Voici quelques bonnes pratiques à suivre lors de l'installation :

Alignement correct : assurez-vous que l'actionneur est correctement aligné avec l'objet surveillé pour éviter de fausses lectures ou un dysfonctionnement.

Montage sécurisé : utilisez le matériel de montage approprié pour fixer l'interrupteur en place, évitant ainsi les vibrations ou les mouvements involontaires.

Gestion des câbles : acheminez et protégez correctement les câbles du commutateur pour éviter tout dommage et maintenir les connexions électriques.

Étiquetage et documentation : étiquetez clairement chaque commutateur pour une identification facile et conservez une documentation appropriée pour faciliter la maintenance et le dépannage.

En conclusion, les interrupteurs de fin de course sont des dispositifs essentiels en milieu industriel, permettant un contrôle et une surveillance précis. Comprendre leurs principes fondamentaux, leurs applications, leur technologie et les bonnes pratiques de sélection, de maintenance et d'installation est essentiel pour toute personne impliquée dans l'automatisation industrielle. En appliquant ces directives, les professionnels de l'industrie peuvent exploiter la puissance des interrupteurs de fin de course pour accroître l'efficacité, la sécurité et la productivité de leurs opérations.

Besoin de commandes en gros ou de recommandations d'experts sur SB-LS ?

Vous souhaitez commander des SB-LS en gros ou avez besoin d'aide pour choisir la solution industrielle idéale ? Notre équipe est là pour vous aider avec des devis personnalisés, des recommandations de produits et des conseils techniques. Que vous soyez électricien, entrepreneur ou chef d'entreprise, nous proposons des solutions sur mesure pour répondre à vos besoins.

📩 Contactez-nous ou discutez avec nous en direct pour une assistance instantanée !

Découvrez notre collection mensuelle d'offres de folie !

Profitez de réductions exceptionnelles dans notre magasin ! Découvrez les meilleures offres :

Explorez ces catégories maintenant et profitez des meilleures offres avant qu'elles ne disparaissent !

-

Tous les produits de notre gamme – Des produits de qualité supérieure sélectionnés avec soin pour vous.

-

Meilleures ventes – Articles préférés des clients et articles très demandés.

-

Offres spéciales et soldes Watts – Remises à durée limitée sur des produits incontournables.

-

Watts New – Nouveautés et dernières innovations.

-

Toutes les collections – Explorez tout ce que nous avons à offrir.

Explorez ces catégories maintenant et profitez des meilleures offres avant qu'elles ne disparaissent !

N'oubliez pas de consulter nos remises massives jusqu'à épuisement des stocks !