Disjoncteurs

278 produits

Affiche 1 - 48 de 278 produits

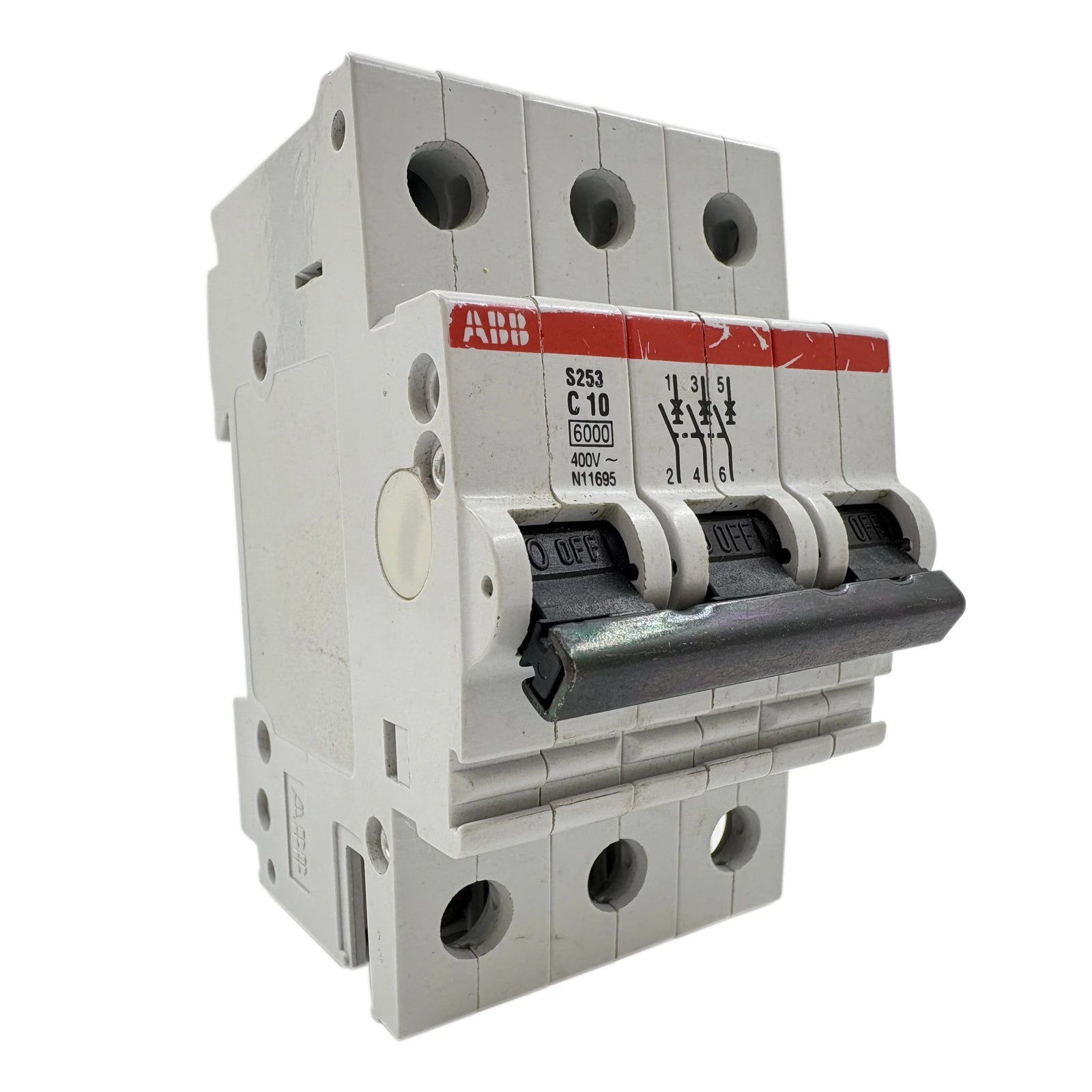

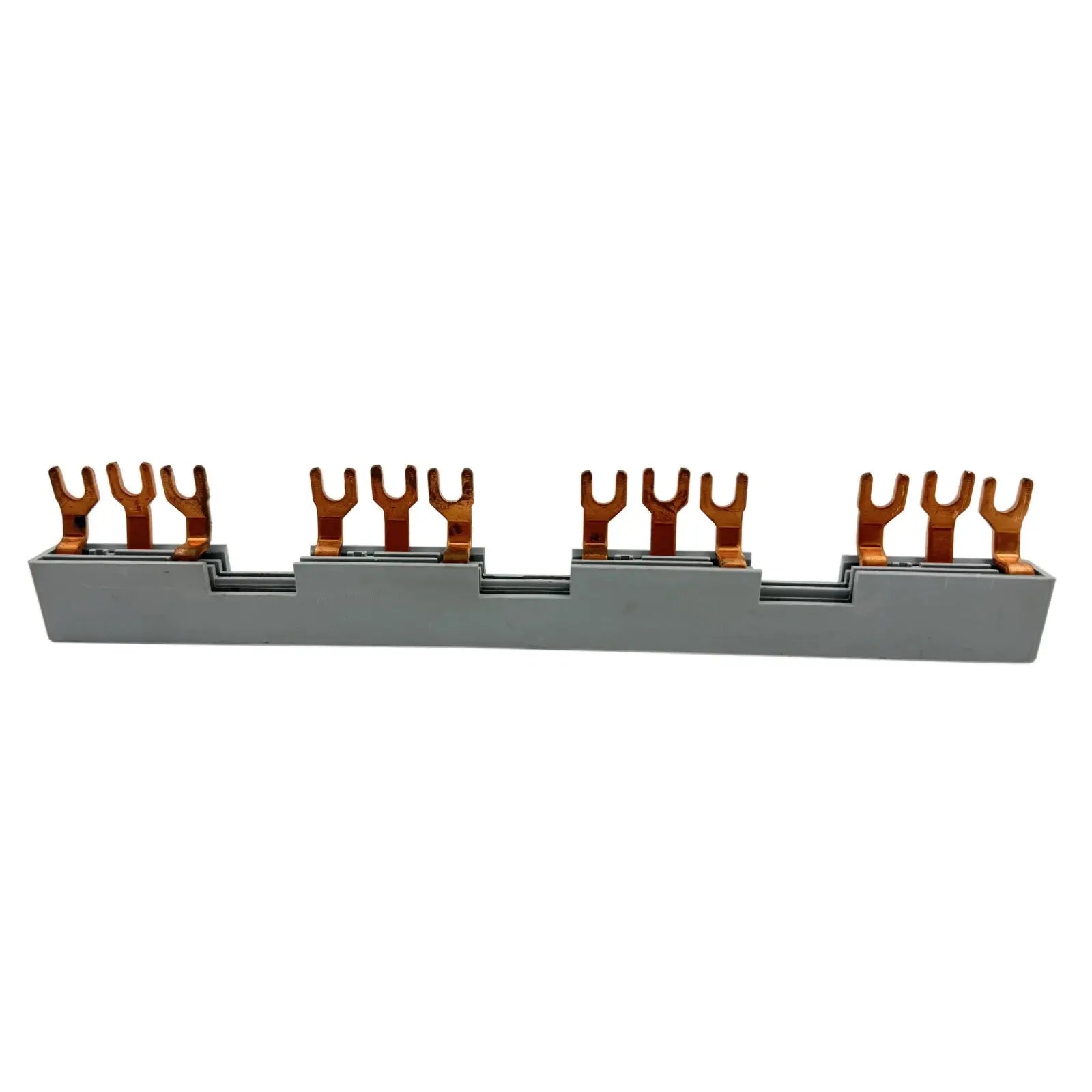

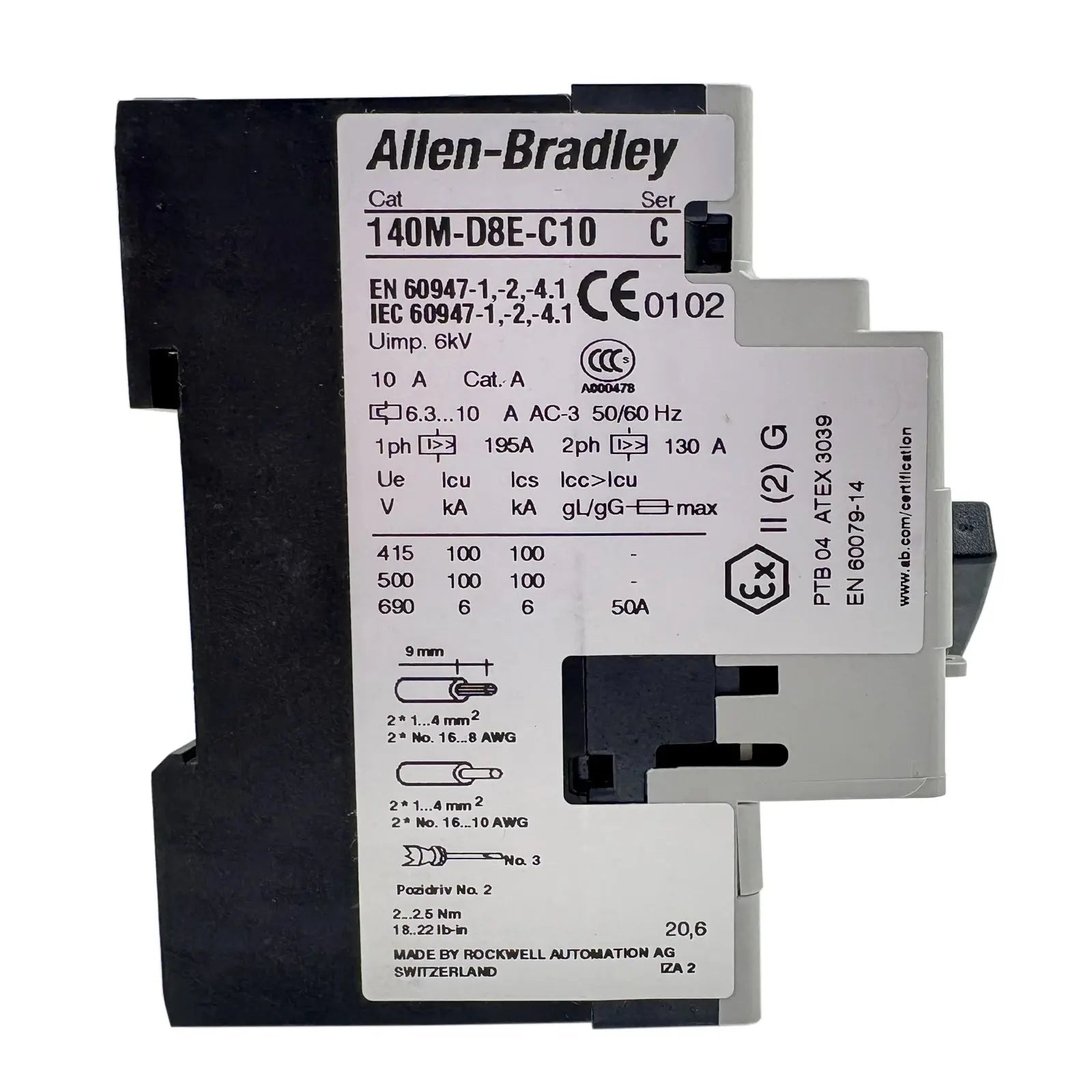

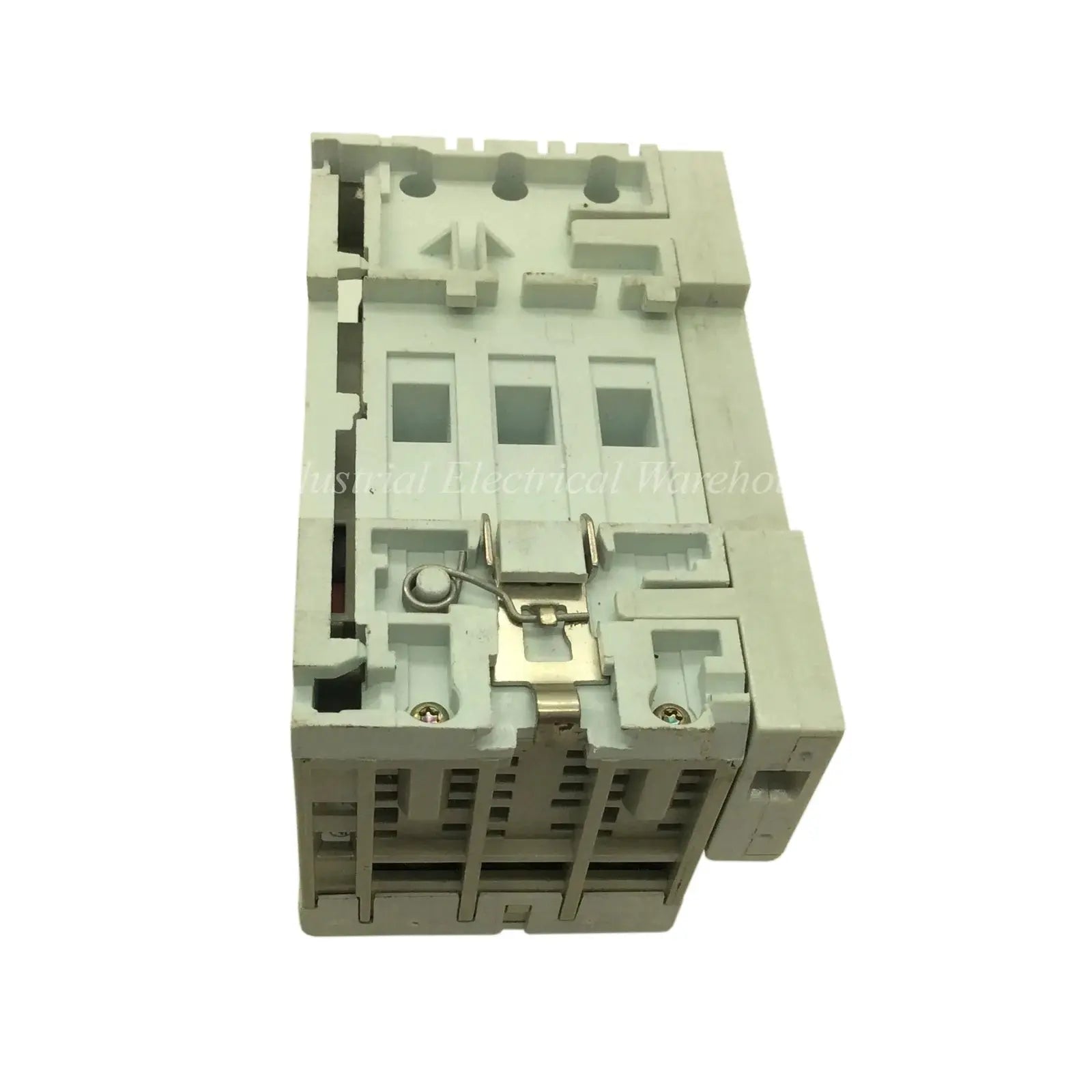

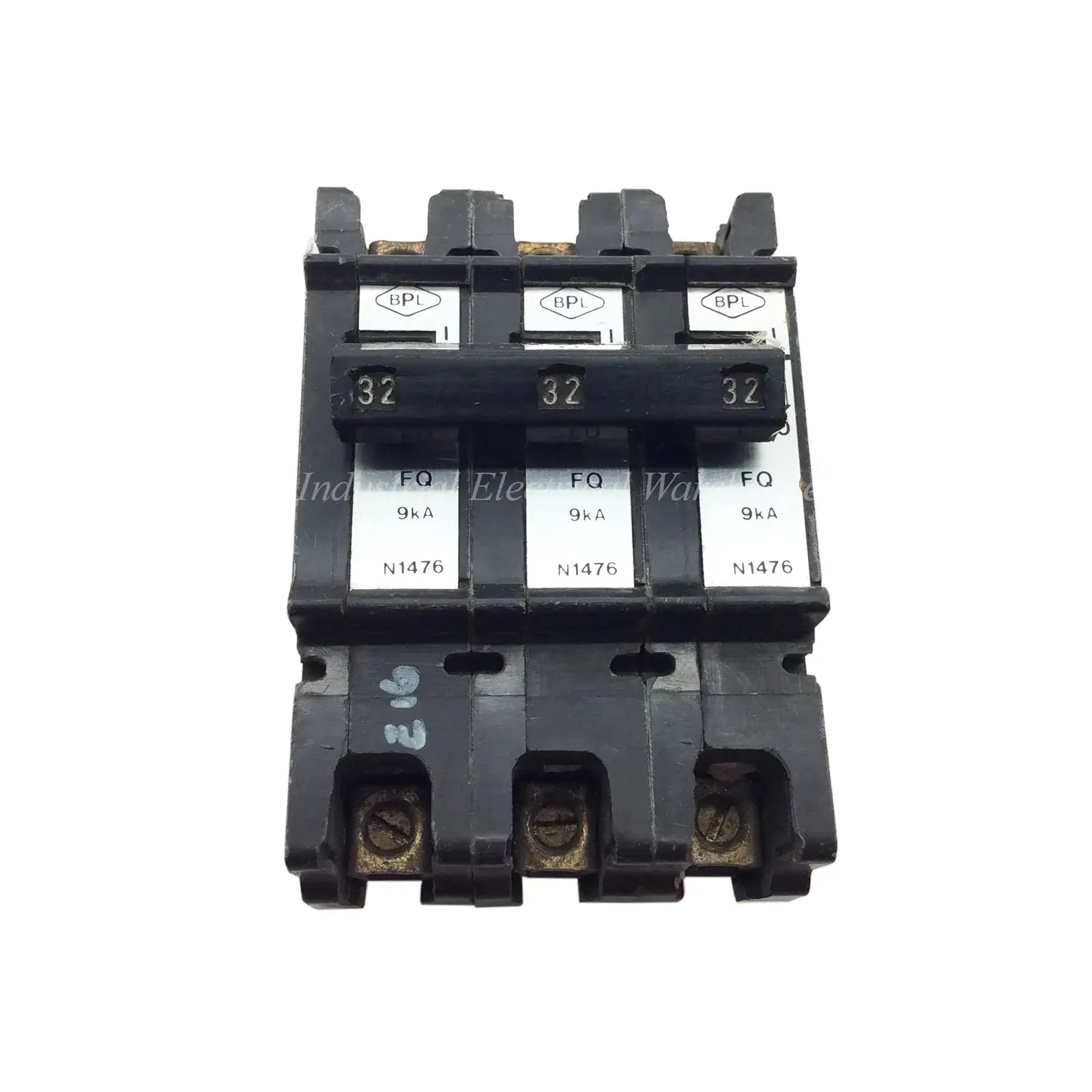

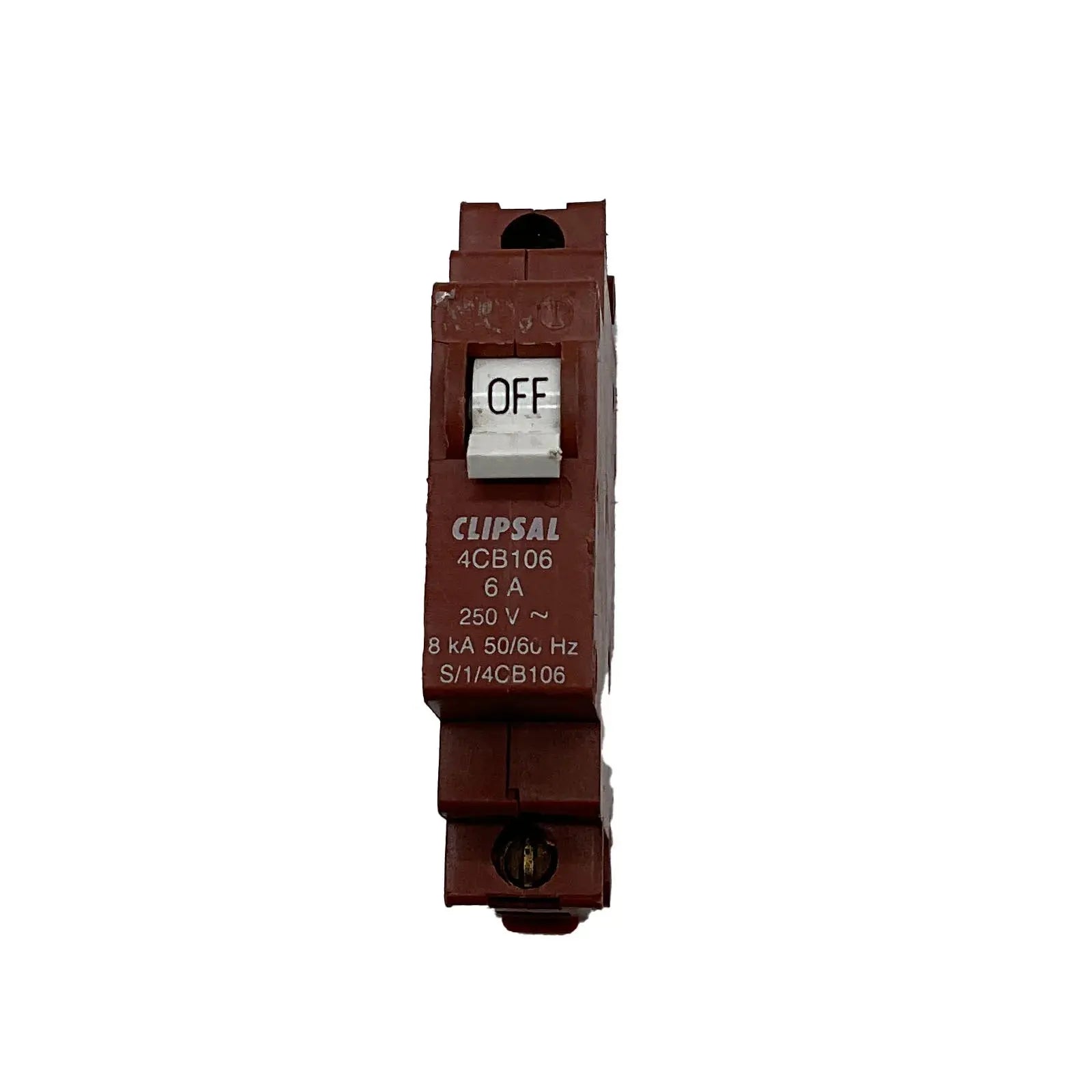

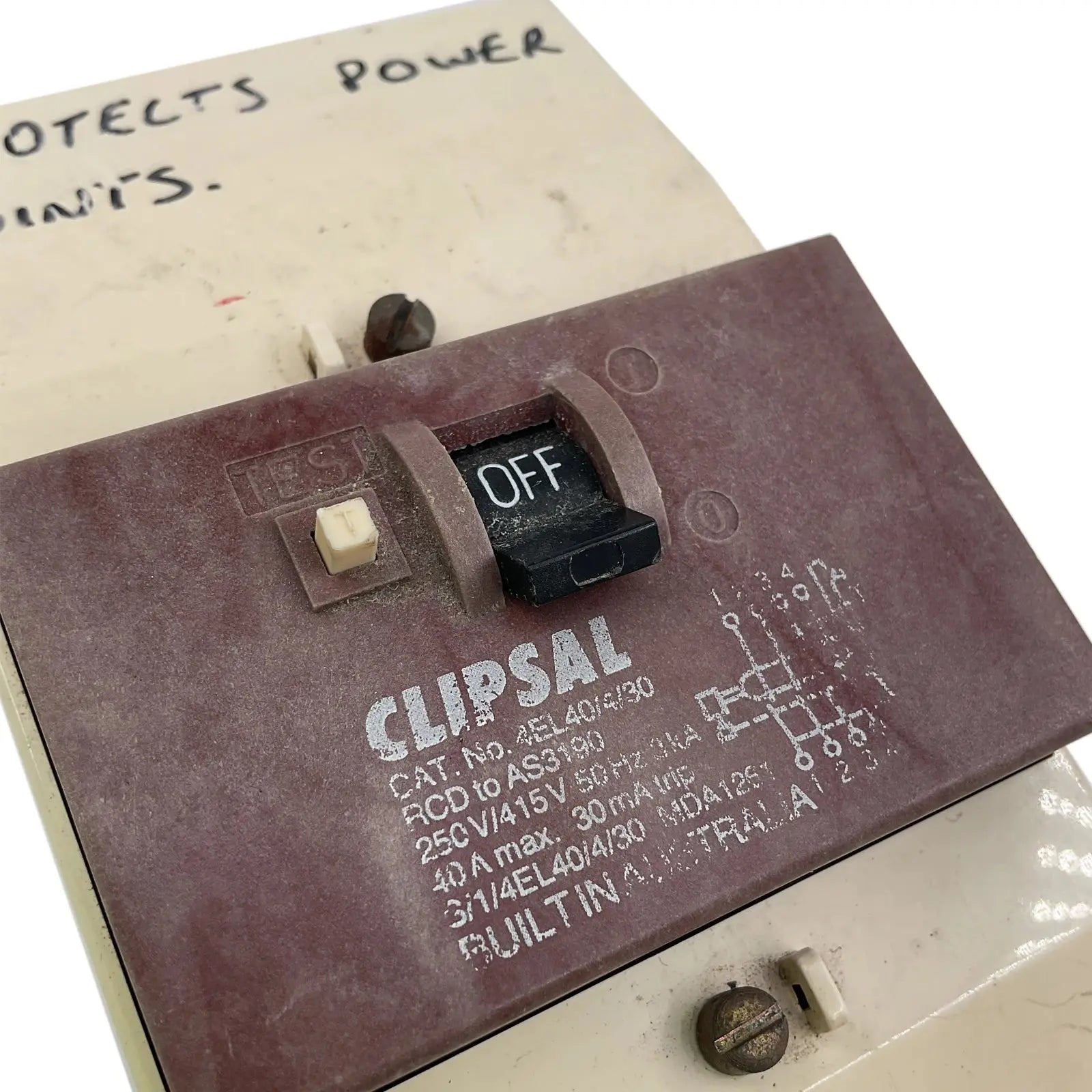

Disjoncteur – Protection électrique fiable

Le disjoncteur est un dispositif de sécurité essentiel conçu pour protéger les installations électriques contre les surcharges, les courts-circuits et les défauts. Il coupe automatiquement le courant en cas d'anomalie, évitant ainsi d'endommager les équipements et réduisant les risques d'incendie ou d'électrocution. Notre gamme propose des solutions pour les applications résidentielles, commerciales et industrielles, garantissant un fonctionnement fiable en toutes circonstances.

Comment nos disjoncteurs garantissent-ils la sécurité et la fiabilité ?

Chaque disjoncteur de notre gamme est conçu avec précision et testé selon les normes industrielles les plus strictes. Qu'il s'agisse de disjoncteurs miniatures, moulés ou différentiels, chaque unité est conçue pour une performance durable, une réponse rapide et une protection constante même dans des conditions exigeantes.

Besoin de commandes en gros ou de recommandations d'experts sur les disjoncteurs ?

Notre équipe vous propose des conseils techniques, des devis personnalisés et des recommandations de produits adaptés aux exigences de votre projet. Électricien, entrepreneur ou gestionnaire d'installations, nous sommes là pour vous aider à choisir le disjoncteur idéal.

📩 Contactez-nous ou discutez avec nous en direct pour obtenir une assistance immédiate !

Découvrez notre collection d'offres folles du mois !

Ne manquez pas nos super réductions en magasin ! Découvrez nos meilleures offres :

Explorez ces catégories dès maintenant et profitez des meilleures offres avant qu'il ne soit trop tard !

- Tous les produits de notre gamme – Des produits de qualité supérieure sélectionnés avec soin pour vous.

- Meilleures ventes – Articles préférés des clients et produits très demandés.

- Offres exceptionnelles et promotions Watts – Réductions à durée limitée sur les produits incontournables.

- Nouveautés Watts – Arrivages récents et dernières innovations.

-

Toutes les collections – Découvrez tout ce que nous avons à vous offrir.

Explorez ces catégories dès maintenant et profitez des meilleures offres avant qu'il ne soit trop tard !

N'oubliez pas de consulter nos remises exceptionnelles jusqu'à épuisement des stocks !

Vu récemment

Bulletin d'information Watts Current

Restez connecté avec les derniers produits électriques industriels, les offres exclusives et les mises à jour d'experts.

Inscrivez-vous maintenant et ne manquez rien