Écrous et boulons

248 produits

Affiche 49 - 96 de 248 produits

Collection Écrous et Boulons – Des solutions de fixation fiables pour tous les secteurs d'activité

Chez Industrial Electrical Warehouse, nous proposons une vaste sélection d'écrous et de boulons pour répondre aux besoins de diverses applications industrielles et électriques. Que vous assembliez des machines, travailliez sur des chantiers de construction ou ayez besoin de composants fiables pour vos systèmes électriques, notre gamme variée d'écrous et de boulons vous garantit des solutions de fixation sûres, durables et performantes. Grâce à un large choix de matériaux et de dimensions, nous avons tout ce qu'il vous faut pour vos exigences spécifiques en matière de fixation.

Pourquoi choisir les écrous et boulons d'Industrial Electrical Warehouse ?

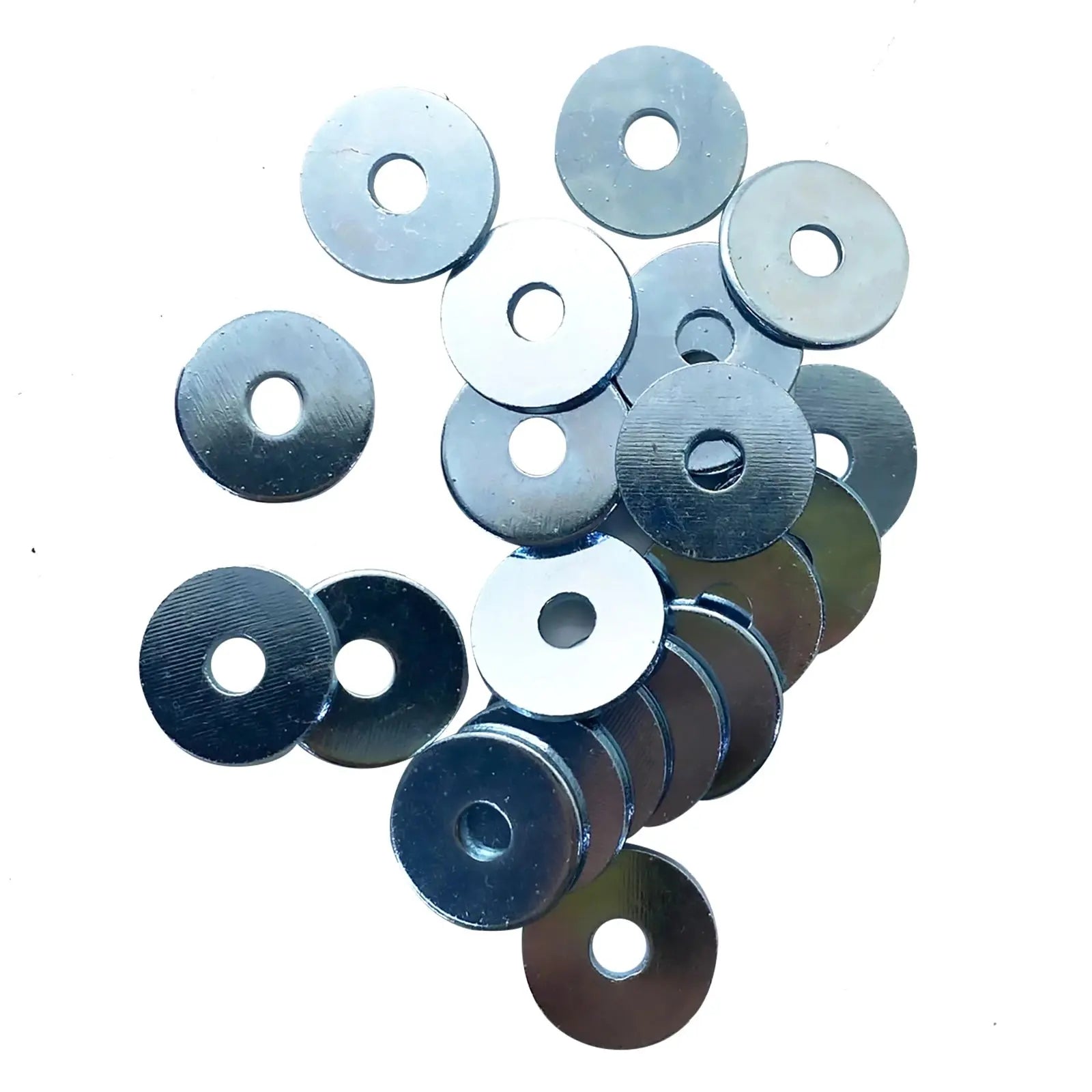

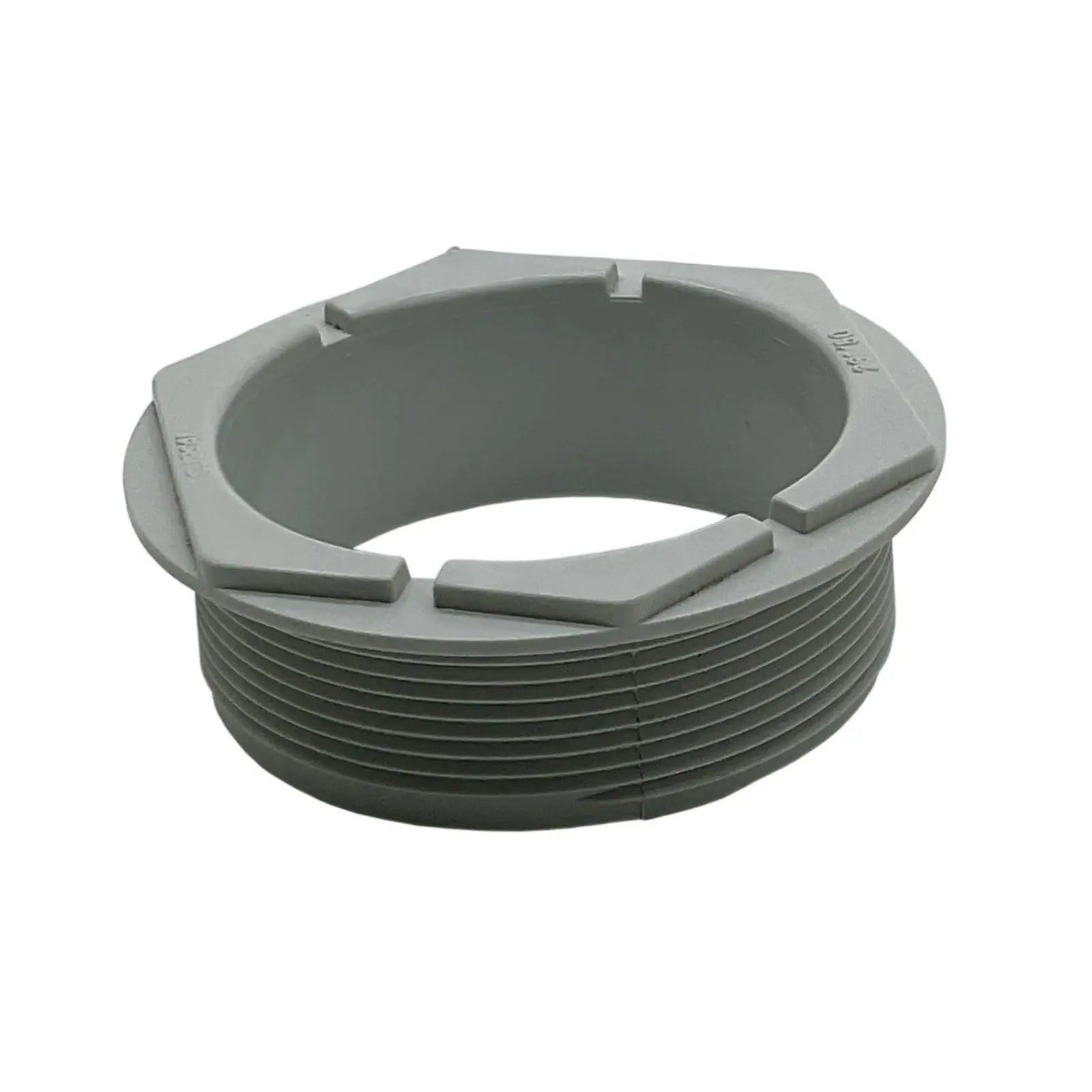

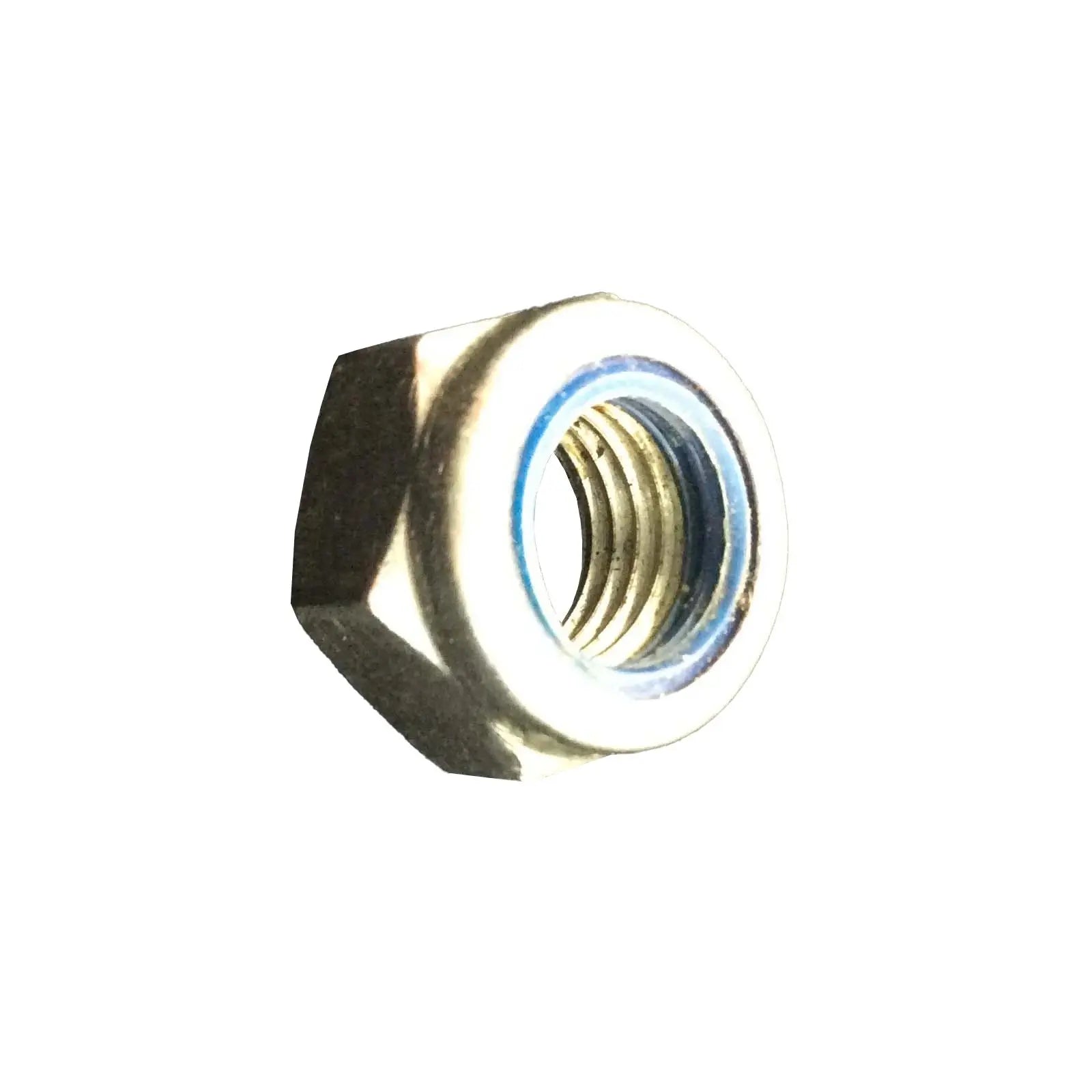

Les écrous et les boulons sont des composants essentiels dans d'innombrables applications, assurant des assemblages sûrs et stables pour un large éventail de secteurs. Notre collection comprend des fixations fabriquées à partir de matériaux de haute qualité tels que l'acier, l'acier inoxydable, le laiton, etc. Nous proposons différentes tailles, types de filetage et finitions afin de garantir une adaptation parfaite à chaque projet, assurant ainsi une durabilité et des performances optimales.

Types d'écrous et de boulons

Cette collection comprend différents types de boulons, tels que des boulons hexagonaux, des boulons à tête carrée et des tire-fonds, chacun conçu pour des applications spécifiques. Vous y trouverez également des écrous comme des écrous hexagonaux, des écrous autobloquants et des écrous papillon, offrant ainsi des solutions polyvalentes pour tous vos besoins de fixation.

Des fixations fiables et durables pour tous vos travaux

Des boulons et écrous standard aux modèles spécialisés comme les boulons d'ancrage et les étriers en U, chaque produit de cette collection est fabriqué à partir de matériaux de haute qualité pour résister aux conditions les plus difficiles. Ces fixations sont conçues pour durer, assurant un maintien sûr et empêchant tout desserrage au fil du temps.

Chez Industrial Electrical Warehouse, nous nous engageons à vous fournir des écrous et des boulons de haute qualité pour répondre à tous vos besoins industriels et électriques. Parcourez notre collection dès aujourd'hui et trouvez la fixation idéale pour votre prochain projet !

Besoin de commandes en gros ou de recommandations d'experts en boulonnerie ?

Vous recherchez des commandes en gros de boulons et écrous ou vous avez besoin d'aide pour choisir la solution industrielle adaptée ? Notre équipe est là pour vous accompagner avec des devis personnalisés, des recommandations de produits et une assistance technique. Que vous soyez électricien, entrepreneur ou chef d'entreprise, nous proposons des solutions sur mesure pour répondre à vos besoins.

📩 Contactez-nous ou discutez avec nous en direct pour obtenir une assistance immédiate !

Découvrez notre collection d'offres folles du mois !

Ne manquez pas nos super réductions en magasin ! Découvrez nos meilleures offres :

Explorez ces catégories dès maintenant et profitez des meilleures offres avant qu'il ne soit trop tard !

- Tous les produits de notre gamme – Des produits de qualité supérieure sélectionnés avec soin pour vous.

- Meilleures ventes – Articles préférés des clients et produits très demandés.

- Offres exceptionnelles et promotions Watts – Réductions à durée limitée sur les produits incontournables.

- Nouveautés Watts – Arrivages récents et dernières innovations.

-

Toutes les collections – Découvrez tout ce que nous avons à vous offrir.

Explorez ces catégories dès maintenant et profitez des meilleures offres avant qu'il ne soit trop tard !

N'oubliez pas de consulter nos remises exceptionnelles jusqu'à épuisement des stocks !

Vu récemment

Bulletin d'information Watts Current

Restez connecté avec les derniers produits électriques industriels, les offres exclusives et les mises à jour d'experts.

Inscrivez-vous maintenant et ne manquez rien